Sour Gas In, Sweet Gas Out

The Gas Sweetening System, GSS, also known as Amine gas treating, refers to removing H2S and CO2 (hydrogen sulfide and carbon dioxide) from natural gas. Carbon Dioxide and Hydrogen Sulfide are often found in natural gas streams.

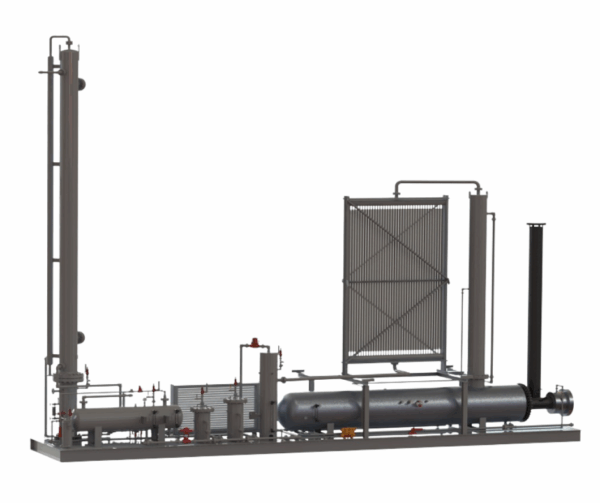

The Gas Sweetening System, GSS, also known as Amine gas treating, refers to removing H2S and CO2 (hydrogen sulfide and carbon dioxide) from natural gas. Carbon Dioxide and Hydrogen Sulfide are often found in natural gas streams.The Amine Plants (GSS) are built in a rugged, all-in-one package to allow easy transportation and installation, which greatly decreases delivery and setup time. CROFT amine plants can also be utilized in split stream applications to treat greater volume amounts of H2S and CO2. Therefore, if the well stabilizes and decreases in volume over time and requires fewer gallons of amine circulation, the excess plants can be removed. This method allows the client to treat only what is specified and avoid having oversized assets in their locations.

CROFT designs and manufactures gas-sweetening Amine Plants (GSS) with rates of up to 10 GPM of amine. Using the parameters for your particular gas stream, we will design the most efficient system to handle your specifications. CROFT will be there every step of the way with design, manufacture, assembly, start-up, and troubleshooting any operational issues that involve the Gas Sweetening System.