The Importance of Dehydrating Natural Gas

Natural gas dehydration is an important step in processing natural gas. Over-saturated gas can cause corrosion, reducing the lifespan of gas processing equipment, and ultimately causing the gas stream to not meet pipeline specifications. If the gas does not meet pipeline specifications of 7 pounds per mmcfd, a natural gas dehydration unit is needed to prevent these harmful effects.

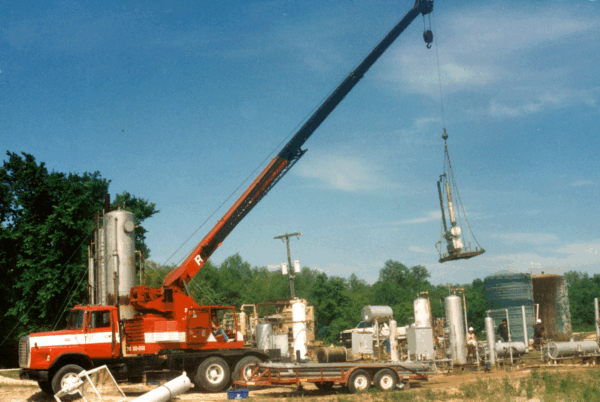

Natural gas is dehydrated by being condensed from vapor into liquid form and then removed by a gas dehydration unit, also known as a gas dehy, using either adsorption or absorption. CROFT offers two types of natural gas dehydration equipment including solid desiccant dehydrators referred to as Passive Dehydration Systems (PDS), and Glycol Dehydrators (TEG).

Dehydrating Natural Gas Products

Croft Production Systems manufactures solid desiccant dehydrators that offer a safe, easy, and effective solution for dehydrating gas. CROFT will properly size these systems to be most efficient for your specifications and we offer flexible leasing contracts to meet your needs.

Our Passive Dehydration System (PDS) is CROFT's preferred system for gas dehydration over glycol dehydrators because the PDS is a simple design without multiple moving parts, open flames, safety hazards, and toxic emissions. This dehydration unit requires less maintenance and is significantly safer for personnel and the environment.

CROFT offers new and refurbished glycol dehydrators that offer optimal performance in varying conditions. As a new manufacturer of glycol units, CROFT has created a design that has improved trouble areas of glycol units, making them more operator-friendly.

The components included on our standard glycol units are typically options from other manufacturers and we offer upgrade options as well for the units such as BTEX units for emissions elimination, Burner Management Systems for exceptional process control and reliability, and safety devices to protect pumps from costly rebuilds.