Multi-Use Injection and No Toxic Emissions

Croft's CIS can be used to solve the following:

- H2S

- High salt content

- Corrosion

- Hydrates

- Scale

- Paraffin

- Foaming

Hydrogen Sulfide (H2S) is a very toxic and pungent gas that causes problems in both the upstream and downstream side of production in the oil and gas industry. CROFT utilizes and highly recommends our own blend of H2Scavenger within our Chemical Injection Systems. This blend has been formulated for our equipment to treat hydrogen sulfide, increase processing efficiency, and result in cost-saving for our customers.

Multi-Use Injection and No Toxic Emissions

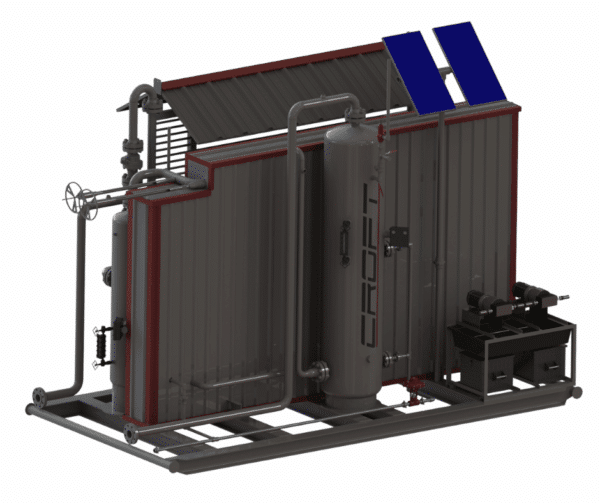

CROFTs Chemical Injection System (CIS) implements a multi-use chemical static mixer. When used for H2S removal, the CIS is a safe and effective alternative to amine plants without requiring permits or large capital investment, operating without emissions and fired vessels. Croft's highly concentrated H2Scavenger efficiently removes H2S, decreasing the scavenger usage.

The CIS is ASME coded and uses solar injection pumps to eliminate emissions and maximize reliability. For H2S removal, the CIS is also NACE compliant.

Features & Benefits

Resources

Gallery

CIS Frequently asked questions

What is a chemical injection system?

A chemical injection system is used to accurately deliver controlled amounts of chemicals into oil and gas processes. These chemicals help prevent corrosion, scale, hydrate formation, foaming, paraffin buildup, and other operational issues that can reduce efficiency and damage equipment.

What makes CROFT’s chemical injection system different?

CROFT systems are designed with field experience in mind. They are built for reliability, accuracy, and ease of maintenance. Our systems are engineered to handle harsh operating conditions, reduce downtime, and deliver consistent chemical dosing you can trust.

Are CROFT systems customizable?

Yes. Each system can be configured to meet your specific flow rates, pressures, chemical types, and site requirements. We offer custom skid designs, pump configurations, tank sizing, and control options.

Can these systems be used in remote locations?

Absolutely. CROFT chemical injection systems are commonly deployed in remote field locations. We offer solar-ready and low-maintenance configurations that are ideal for unmanned or hard-to-access sites.

How easy is maintenance?

Our systems are designed for straightforward maintenance. Components are selected for durability and serviceability, and our team can provide guidance on routine inspections and upkeep to keep your system running efficiently.

Does CROFT provide technical support?

Yes. Our experienced engineers and certified service team are available to assist with system selection, troubleshooting, optimization, and field support.

How do I get a quote or more information?

You can contact CROFT Production Systems directly to discuss your application. Our team will work with you to understand your needs and provide a tailored solution.