The Importance of H2S Removal

Hydrogen Sulfide (H2S) is a very toxic gas that is dangerous for personnel and causes problems in both the upstream and downstream side of production in the oil and gas industry. Due to the detrimental effects of H2S, pipeline companies have specifications in place that prevent gas with high amounts of H2S to be put into the pipeline. CROFT offers three efficient solutions for removing H2S; our Amine Plant (GSS), Iron Oxide System and Chemical Injection System (CIS).

Croft H2S Removal Products

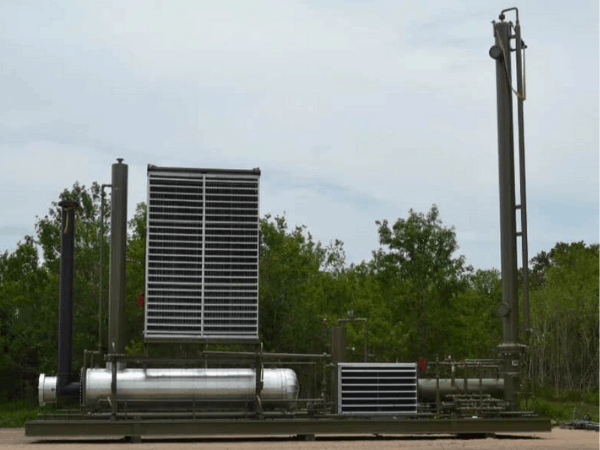

CROFT designs and manufactures Gas Sweetening Systems (GSS), also called Amine Plants. Our amine plants are rugged, all-in-one packages that can be utilized in split stream applications to treat greater volume amounts of H2S and CO2.

CROFT designs and manufactures gas-sweetening amine plants with rates of up to 10 GPM of amine. Using the parameters for your particular gas stream, we will design the most efficient system to handle your specifications.

CROFTs Chemical Injection System (CIS) implements a multi-use chemical static mixer. When used for H2S removal, the CIS is a safe and effective alternative to amine plants without requiring permits or large capital investment, operating without emissions and fired vessels. CROFT’s highly concentrated H2Scavenger efficiently removes H2S, decreasing the scavenger usage.

The CIS is ASME coded and uses solar injection pumps to eliminate emissions and maximize reliability. For H2S removal, the CIS is also NACE compliant.

Our Iron Oxide System (IOS) employs a distinctive gas sweetening technique where iron oxide media in a containment vessel chemically reacts to eliminate H2S from the gas flow. This IOS system effectively removes H2S and other mercaptans, adapting to fluctuating volumes and H2S concentrations. Its affordable media and straightforward operation make it an optimal choice for refining natural gas and biogas.