The Importance of Fuel Gas Conditioning

Although there are many benefits to utilizing fuel gas, there are a few challenges. The compatibility of the field gas BTU and the presence of contaminants such as CO2 and H2S, often make gas unsuitable straight from the well, but this is where CROFT can help. Our Joule Thomson Systems (JTS) and Fuel Gas Conditioning Systems (FCS) offer efficient solutions to improve gas quality.

Croft Production Systems, with its decades of expertise, understands the criticality of this process, recognizing that the quality of conditioned fuel gas directly impacts operational efficiency, equipment longevity, and environmental compliance. Through our equipment and solutions, we endeavor to bring forward the significance of fuel gas conditioning not just as a functional requisite but as a cornerstone for sustainable and efficient energy production.

Fuel Gas Conditioning Products

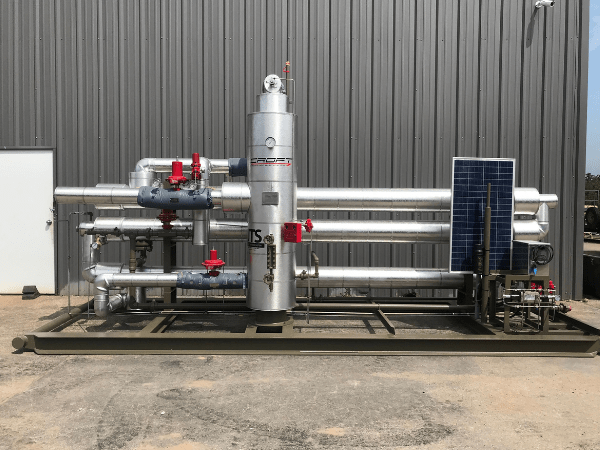

Our Fuel Gas Conditioning System (FCS) takes the high-pressure/high-temperature gas from the compressor's discharge and cools, separates, dehydrates, reduces the BTU, and reduces the pressure to the required fuel system PSI.

With the reduction in the BTU, we can take otherwise unusable fuel from the wellhead and run compressor engines, drilling engines, and hydraulic fracturing engines. By separating the NGL’s and dehydrating the gas stream, we remove most heavier components that often cause engine issues.

Our Joule Thomson Systems lowers the BTU (British Thermal Unit) of the gas stream to sales contract specifications or levels suited for high-speed engines. The JTS removes butane, pentanes, hexanes, and other heavy natural gas components unsuitable for fuel engines.

These systems are pre-assembled and delivered, ready to be installed on location. Consolidated on a single skid, this space-saving system is installed by experienced CROFT personnel and serviced monthly to ensure everything is running smoothly.

Croft produces separators in both horizontal and vertical configurations, available in two-phase or three-phase versions. Proper separation is crucial to prevent slugging and particulates from compromising downstream processing equipment. Croft's separators come equipped with integrated instrumentation, housed in a robust, single package, facilitating easier transportation and installation, thereby reducing delivery and setup durations.