Multi-Use Injection and No Toxic Emissions

The Chemical Injection System (CIS) was originally designed for H2S removal and has been reformulated as a multi-use chemical static mixer implementation. The CIS ensures chemicals are being fully utilized, decreasing the amount needed, and ultimately, saving money. When used for H2S removal, the CIS is a safe and effective alternative to amine plants without the need for permits or large capital investment, operating without emissions and fired vessels. CROFT’s highly concentrated H2Scavenger removes H2S while decreasing the number of gallons required.

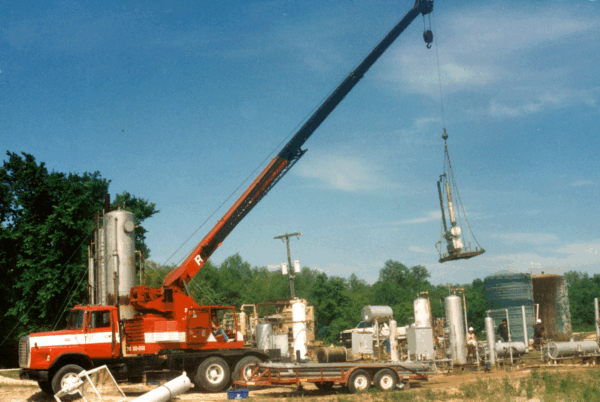

The CIS is ASME coded and uses solar injection pumps to eliminate emissions and maximize reliability. For H2S removal, the CIS is also NACE compliant. The system is installed by experienced CROFT personnel, who will make sure everything is running smoothly and will continue to monitor the system on a monthly basis.

Due to the request of our clients, CROFT’s CIS can now be used to solve the following:

- H2S

- High salt content

- Corrosion

- Hydrates

- Scale

- Paraffin

- Foaming

Hydrogen Sulfide (H2S) is a very toxic and pungent gas that causes problems in both the upstream and downstream side of production in the oil and gas industry. CROFT utilizes and highly recommends our own blend of H2Scavenger within our Chemical Injection Systems. This blend has been formulated for our equipment to treat hydrogen sulfide, increase processing efficiency, and result in cost-saving for our customers.