Solutions for Cooling Natural Gas

Why Cool Natural Gas?

Why Cool Natural Gas?

Cooling natural gas has numerous benefits for equipment operations such as:

- reducing the water content of the gas which reduces work on dehydrators

- recovery of NGL’s which increases oil production

Our powered and non-powered Ambient Coolers are new or refurbished units with proven reliability at very competitive rates. Both systems are available for lease or sale.

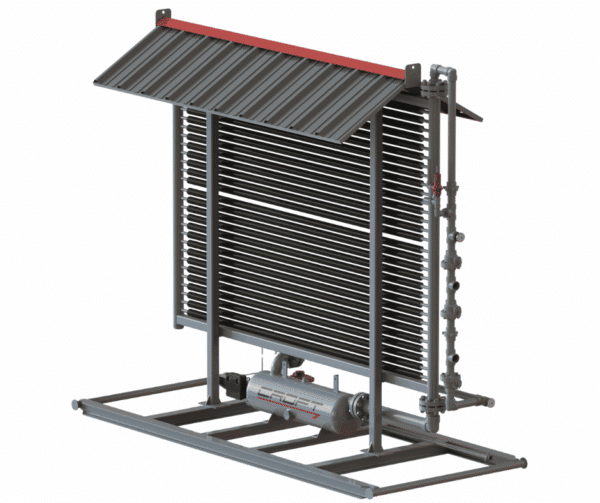

Non-Powered Ambient Cooling Systems

Our non-powered Ambient Cooling Systems (ACS) passively cool the gas through a multi-pass, fin tube cooler section and can be equipped with optional after-cooling separation for condensed liquid removal. Cooler sections can be linked together to increase cooling effectiveness.

How It Works

The Ambient Cooling System uses a roof to reflect the sun's rays and dispel heat from above. The open structure allows for prevailing winds to lower the temperature of hot gas that is entering the system so that a cool gas stream can flow out of the equipment.

Powered Ambient Cooling Systems

Our powered Ambient Cooling Systems (ACS) actively cool the gas using a motor-driven fan to force air through a fin tube cooler bundle. Our fans are either electrically powered or utilize a reliable, natural gas-powered engine.

Forced Air Coolers

Utilizing Fresco Thermal's patent-pending cooling technology allows the Aeris Cooler line to have maximum modularity and fit most natural gas cooling applications.

Technology

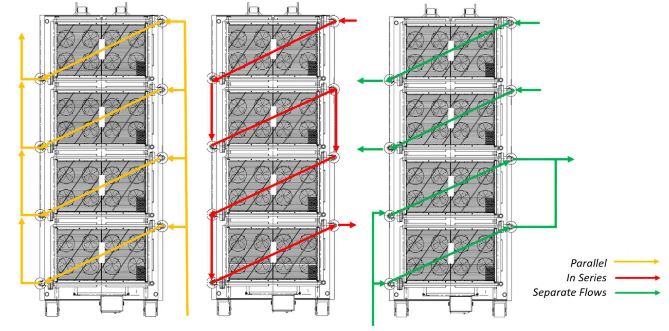

The patent-pending design of the Aeris Cooling Systems creates maximum flexibility that allows up to four individual cells to be operated independently in either automatic or manual mode so that it can run in any combination of parallel, series or separate process flows. Each cell is fitted with 2" NPT connections to allow for individual relief valves based on conditions and preferences.

Flexibility

The patent-pending design of the Aeris Cooling Systems creates maximum flexibility that allows up to four individual cells to be operated independently in either automatic or manual mode so that it can run in any combination of parallel, series, or separate process flows. Each cell is fitted with 2" NPT connections to allow for individual relief valves based upon conditions and preferences.

Mobility

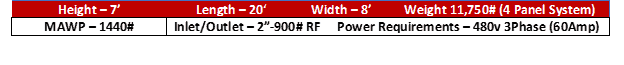

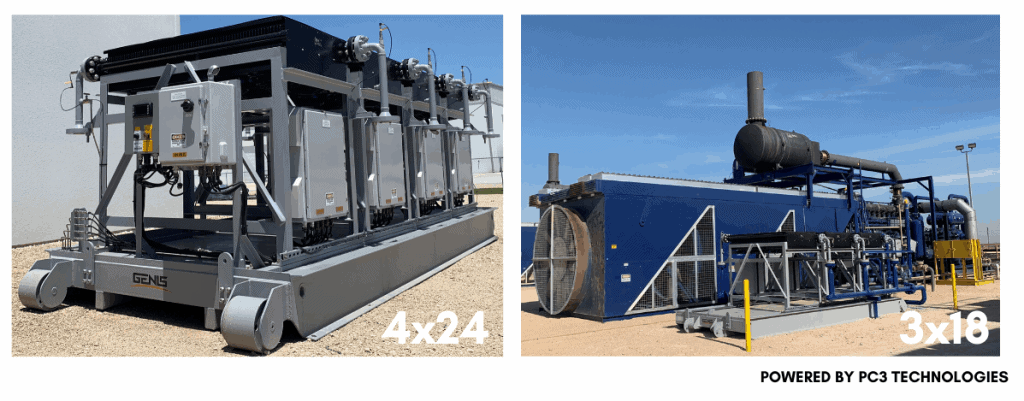

Aeris Cooling Systems are designed to fit into any standard shipping container and not be a permit load. This can save money on transportation costs. The standard size of the Aeris 4 X 24 is 7' tall, 20' long and 8' wide and weighs around 11,750 lbs. This can be lifted by crane or rolling tailboard, but there is an added option of using a roll-off truck for added precision and cost reduction.

Features & Benefits

Resources

Size Options

Gallery

Learn more about CROFT's Fin Fan Cleaning Services here:

ACS frequently asked questions

What makes CROFT ACS coolers different?

CROFT ACS coolers are designed with real field conditions in mind. Benefits include:

Heavy-duty construction for oilfield use

Efficient heat transfer design

Reduced operating costs through improved thermal performance

Serviceable components for easier maintenance

Custom configurations for specific applications

Are CROFT ACS coolers customizable?

Yes. CROFT ACS coolers can be customized to meet your operating conditions, including:

Cooling duty requirements

Flow rates and pressures

Fan configurations

Motor types (electric or other site-specific options)

Skid-mounted packages

Coatings and materials for corrosive environments

Can CROFT ACS coolers operate in extreme climates?

Absolutely. CROFT designs ACS coolers for operation in hot, cold, dusty, and harsh environments. Units can be equipped with features to improve performance in high ambient temperatures and challenging field conditions.

How do ACS coolers improve operational efficiency?

By effectively controlling temperatures, ACS coolers help prevent overheating, reduce equipment stress, improve process stability, and extend the life of compressors, pumps, and other critical equipment.

How do I select the right ACS cooler?

Proper selection depends on your heat load, ambient conditions, process fluid properties, and available footprint. CROFT’s experienced team can assist with sizing and specification to ensure optimal performance.