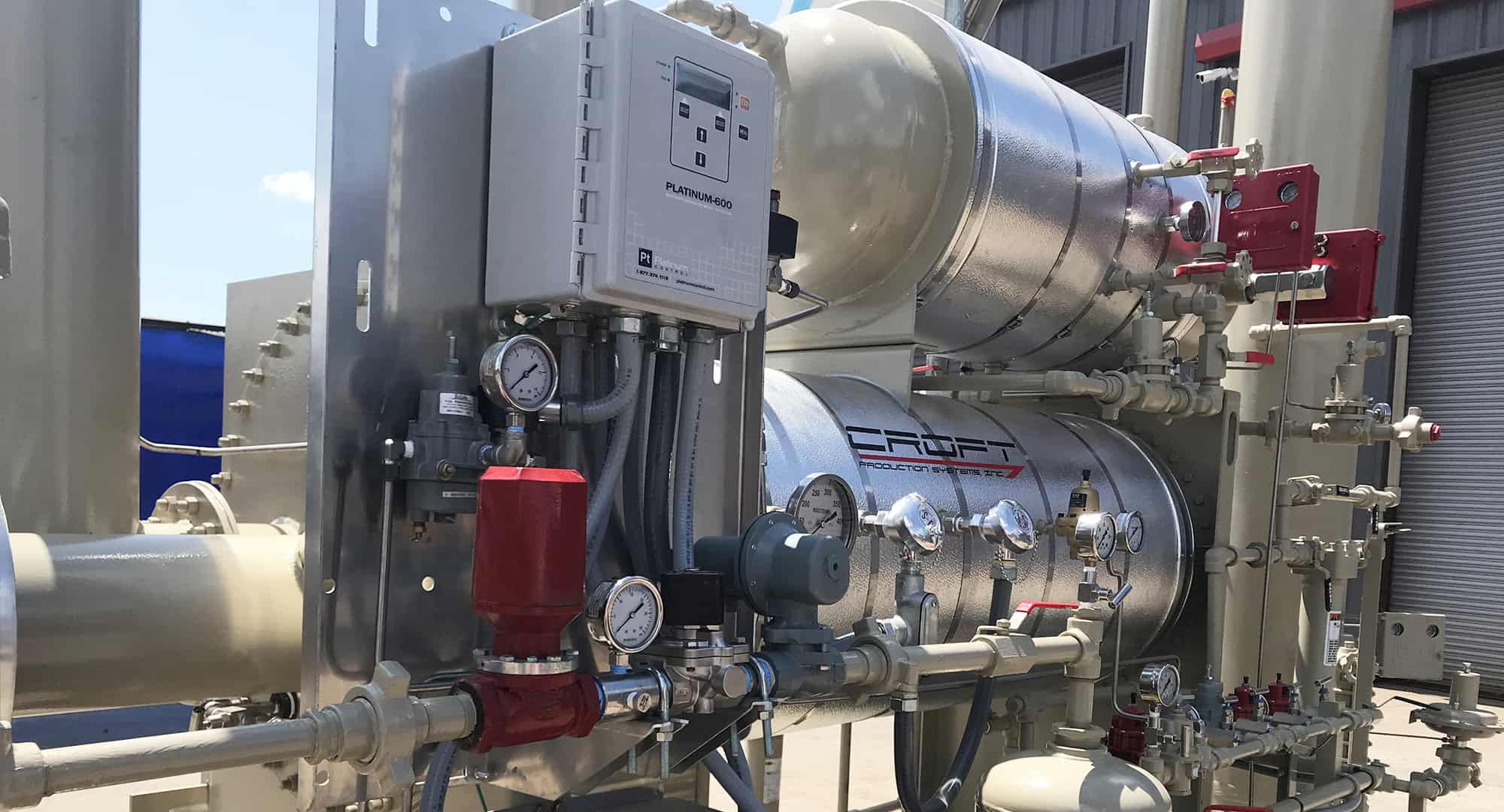

Revolutionize Your Oil and Gas Processing with Top-of-the-Line Glycol Dehydrator Services!

We provide technical diagnostics for all major brands and manufacturers of glycol systems. Our depth of experience means we can offer startup assistance, emergency troubleshooting, efficiency evaluation and routine preventative maintenance and technical solutions to ensure your operations operate efficiently with minimal downtown. We’re experienced in analyzing laboratory results of your glycol samples and thus delivering solutions that are specific to your equipment’s issue.

Startup Assistance

CROFT provides startup assistance on glycol systems because we understand the frustration of balancing until the optimal equilibrium is achieved.

Efficiency Evaluation

CROFT technicians will go to location and observe operations filling out a 50 point checklist report that will be sent to CROFT reliability engineer along with samples. Some of the points of inspection will include PH levels of glycol, comprehensive glycol analysis, burner combustion and many more. This efficiency report will then be shipped to operator with recommendations to increase processing efficiency.

Dehydrator Monthly Preventative Maintenance Program

CROFT technicians during preventive maintenance monthly program will provides various services, we provide the following replacement parts: Controls, Pumps, Filters, Packing, Gauges, and Instrumentation. We do not want to remove the daily tasks of maintaining equipment but more have a wellness check and monitor the benchmark results over time.

Glycol analysis, as part of a proactive maintenance program, often allows operations the time to determine the origin and source of liquid carryover (both oil and saltwater) before expensive chemical and/or manual cleaning becomes a necessity. Some of the warning signs to be aware of are glycol loss, glycol foaming, high pipeline dew points, early pump failure, and corrosion. These service reports will then be sent to client’s field personnel.

Glycol Dehydrator Training

CROFT understand that training has a direct impact on your organizations processing and performance. There are multiple tiers of training support that CROFT can accommodate from onsite training to web based simulation analysis because we understand every organization is different you can speak with a sales representative to look at what best benefits your team.