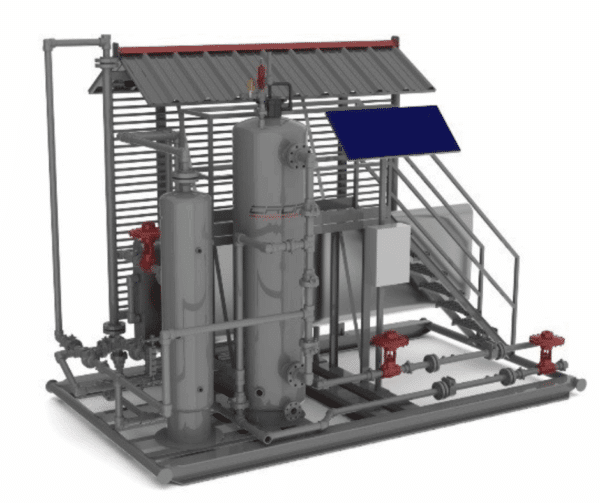

Croft’s All-in-one Fuel Gas Conditioning System

Fuel Gas Conditioning System Applications

- Compressor station fuel gas

- Artificial lift fuel gas

- Frac rig fuel gas

- Drilling rig fuel gas

- Generator fuel gas

- Instrumentation gas

Unprocessed Gas Conditioning FCS - 25 / 50 / 100 / 500

This advanced equipment is designed primarily to process raw natural gas as well as to remove water, condensates, and particulates from the well headstream; to provide a clean, dehydrated, and consistent fuel gas.

Processed Gas Conditioning PG - 100 / 500

This advanced equipment is designed specifically to remove particulates and free liquids from gas streams for utilization in high-speed gas engines and other bi-fuel applications that require a safe, clean gas.

FCS frequently asked questions

Why is fuel conditioning important?

Unconditioned fuel gas can contain:

Liquids and aerosols

Dirt, rust, and particulate

Compressor oil carryover

Inconsistent pressure and temperature

These issues can lead to poor combustion, equipment damage, unplanned downtime, and increased operating costs. A CROFT FCS helps eliminate these risks.

Are CROFT FCS packages customizable?

Yes. CROFT designs each Fuel Conditioning System to match your specific operating conditions, including:

Gas composition

Flow rate requirements

Operating pressures and temperatures

Site footprint

Applicable codes and standards

How does an FCS improve equipment reliability?

By delivering clean, dry, and stable fuel gas, CROFT FCS packages help:

Prevent fouling and plugging

Reduce wear on engines and turbines

Improve combustion efficiency

Lower maintenance frequency

Extend equipment life

Can CROFT help with system sizing and specification?

Yes. CROFT’s engineering team works closely with operators and EPCs to properly size and configure FCS packages for optimal performance and compliance with equipment manufacturer requirements.

How do I get pricing for a CROFT FCS?

To request a quote or discuss your application, contact CROFT Production Systems. Our team will evaluate your fuel gas requirements and recommend a solution tailored to your operation.