Glycol Dehydration Units

Many pipelines or gathering systems require the removal of water vapor from natural gas, also known as natural gas dehydration. This dehydration or water dewpoint reduction of the gas reduces corrosion in pipelines and prevents the formation of hydrates that can block pipelines.

Many pipelines or gathering systems require the removal of water vapor from natural gas, also known as natural gas dehydration. This dehydration or water dewpoint reduction of the gas reduces corrosion in pipelines and prevents the formation of hydrates that can block pipelines.

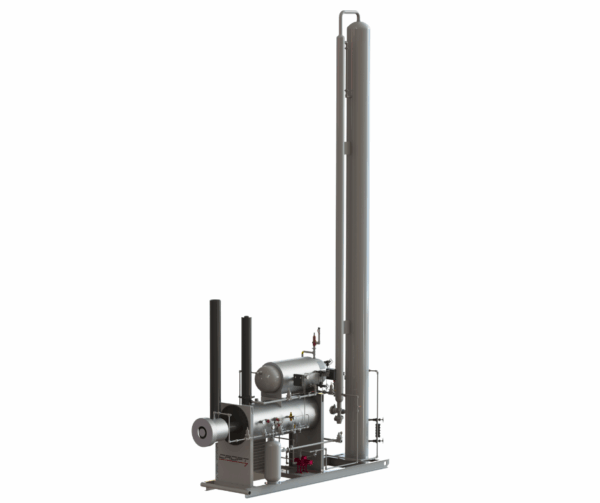

The most common method of dehydrating natural gas in the field is by using glycol dehydrators or TEG units. This method of gas dehydration typically utilizes Tri-ethylene Glycol (TEG) to absorb the water vapor from the natural gas and then regenerate the glycol for continuous reuse in the unit. Standard units are designed to meet a water content outlet specification of less than 7 lbs./MMcf but an upgraded unit can meet specifications of less than 3 lbs./MMcf.

New and Refurbished Glycol Dehydrators

As a refurbisher of glycol units or dehy units, CROFT has seen decades of dehydration units used under varying conditions and has developed a testing and inspection plan for areas of concern and additions and changes that are incorporated into different designs to give optimal performance.

As a new manufacturer of glycol units, we have taken the optimal design choices across many units and improved trouble areas to provide robust and operator-friendly units.

The components included on our standard glycol units are typically options from other manufacturers. We believe certain features are required for a properly functioning dehydration unit and our goal is to minimize operational issues while exceeding performance requirements.

Components & Upgrades for Glycol Dehydration Units

We have numerous upgrade options for glycol units such as BTEX units for emissions elimination, Burner Management Systems for exceptional process control and reliability, and safety devices to protect pumps from costly rebuilds.

- BTEX Units-BTEX units or BTEX condenser units are accessories or upgrades for glycol dehydration units. BTEX condensers are often used to meet both safety and environmental regulations. "BTEX" stands for Benzene, Toluene, Ethylbenzene, and Xylene, which are harmful elements that are common in crude oil and gas production. In addition to reducing BTEX emissions, BTEX units also reduce operating costs by recovering sellable concentrates.

- Burner Management Systems (BMS)- Burner Management Systems or BMS are safety devices that provide temperature control on glycol dehy units. Burner Management Systems allow for safe start-ups, emergency shutdowns, and remote monitoring of burners. These features also mean that Burner Management Systems can greatly reduce emissions of TEG Units.

Glycol Dehydration Process - How it Works

A glycol dehydration unit is comprised of two major components: the contact tower, and the regeneration skid. Gas enters the bottom of the contact tower, also known as an absorber. At the same time, lean glycol is pumped into the top of the tower. The gas contacts the glycol through special internals in the tower to facilitate the absorption of the water vapor. Typical glycol tower internals are chosen depending on the parameters of the application and tower sizing required. Once the glycol reaches the bottom of the contactor tower, it is sent to the regeneration skid to remove the absorbed water. The glycol will be run through separation to remove gas and oils it may have picked up and then filtered. It will then be heated through heat exchangers and enter the reboiler still column where it will be heated to 375-400*F to boil the water out of the glycol. After the reboiler, it is pumped back to the contact tower to continue the regenerative process.

Glycol Unit Sizing

The sizing of a glycol natural gas dehydration unit is based on determining the correct contact tower to pair with a regeneration skid.

The contact tower size is based on the volume, pressure, internals used, water contact entering the unit, and the outlet water content required. Random packing is used for smaller diameter towers typically under 20” diameter. Bubble cap trays are the most common and typically used for 20”-60” diameter towers and contain 6-10 trays depending on application parameters. Structured packing is typically used on larger volume applications and can handle higher volumes than bubble caps with the same diameter tower.

Regeneration systems are sized for the circulation rate required to remove the water vapor from the natural gas stream. Smaller regeneration skids can be paired with larger towers for applications where minimal water vapor removal is required or a larger regeneration skid may be required for applications where high water content removal is needed.

Operator-friendly Glycol Dehydration Units

Croft offers new and refurbished glycol dehydrators that offer optimal performance in varying conditions. As a new manufacturer of glycol units, CROFT has created a design that has improved the trouble areas of glycol units, making them more operator-friendly.

The components included on our standard glycol units are typically options from other manufacturers and we offer upgrade options as well for the units such as BTEX units for emissions elimination, Burner Management Systems for exceptional process control and reliability, and safety devices to protect pumps from costly rebuilds.

Natural Gas Absorption

Glycol units, or TEG Units, operate using an absorption process to dehydrate natural gas. This works by lean glycol being pumped to the top of an absorber where the glycol will meet the wet natural gas stream and remove water by physical absorption. Once the glycol removes the water from the gas stream, the rich glycol is carried out of the bottom of the column. The dry natural gas then leaves the top of the absorption column and is fed either to a pipeline system or to a gas plant.

TEG frequently asked questions

What is a TEG dehydrator in oil and gas operations?

A TEG dehydrator (Triethylene Glycol Dehydration Unit) is a system used to remove water vapor from natural gas. Removing water is critical to prevent hydrate formation, corrosion, pipeline damage, and off-spec gas that can fail to meet sales or transmission requirements.

Why is gas dehydration important?

Wet gas can cause serious operational issues, including:

Hydrate formation and line freezing

Internal corrosion of pipelines and equipment

Reduced gas quality

Potential shutdowns and safety risks

Proper dehydration with a CROFT TEG unit helps protect your assets and ensures your gas meets pipeline specifications.

Are CROFT TEG dehydrators customizable?

Yes. CROFT designs each TEG system based on your operating conditions, including:

Gas flow rates

Inlet and outlet water content targets

Operating pressure and temperature

Ambient conditions

Space and footprint requirements

Can CROFT provide upgrades to existing TEG systems?

Yes. CROFT provides retrofit solutions, performance upgrades, and optimization services for existing glycol dehydrators, helping improve efficiency, reduce emissions, and extend equipment life.

Does CROFT offer turnkey TEG dehydration packages?

Yes. CROFT can supply complete turnkey TEG dehydrator packages, including vessels, piping, instrumentation, and supporting components for simplified installation and startup.