TEG Equipment Overhaul & Cleanout

Equipment Overhaul and Cleanout services have been used for many different areas of processing equipment primarily in glycol dehydration. Most customers dread having to conduct a full cleanout of a TEG dehydrator or glycol dehydrator. The cleanout sometimes implies shutdowns or a drop in capacity. That is why CROFT's professional overhaul crew's experience decreases downtime without jeopardizing quality or safety.

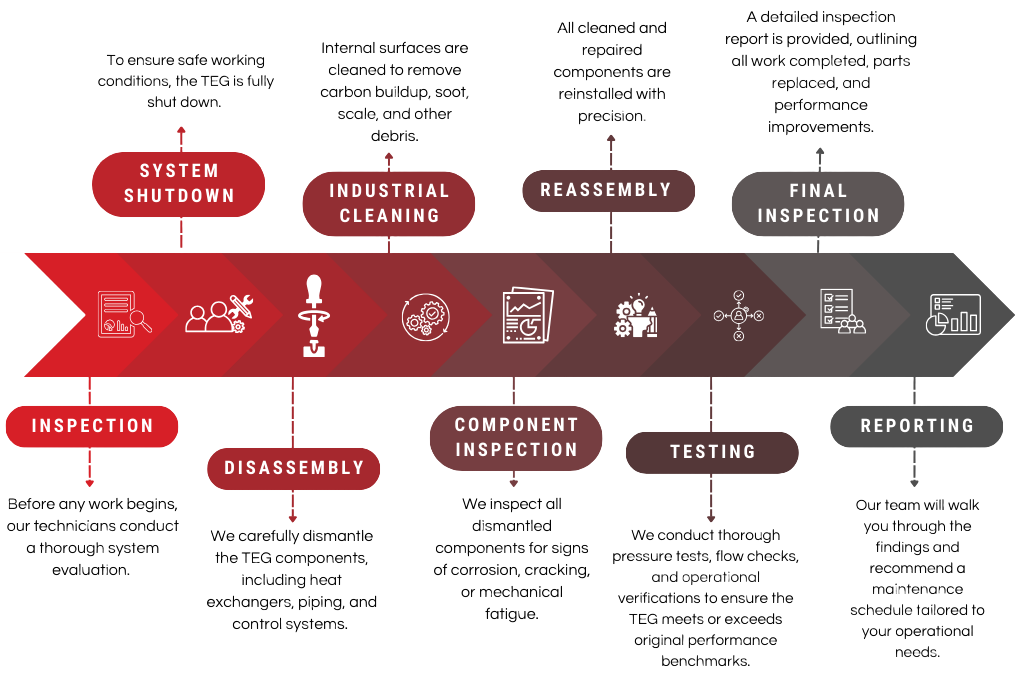

Our Equipment & Overhaul Service process:

Hydrolancing

As part of CROFT’s Equipment Overhaul and Cleanout Service Team, we offer professional hydrolancing to restore your equipment to peak performance. Our high-pressure water jetting process effectively removes scale, debris, and buildup from vessels, exchangers, and pipelines without causing damage to the equipment. Hydrolancing not only improves efficiency but also extends the life of your system by ensuring a thorough, safe, and environmentally friendly clean. Trust CROFT’s experienced technicians to deliver precision cleaning that keeps your operations running smoothly and reliably.

Schedule a call for TEG Cleanout Today

Contact a sales representative to set up a call to get this process started.

Frequently Asked Questions:

What is a TEG overhaul?

A TEG overhaul involves a full inspection, disassembly, deep cleaning, and reassembly of the unit. It's essential maintenance to ensure your equipment operates efficiently, reliably, and safely.

Why choose CROFT Production Systems for the job?

CROFT brings decades of experience, certified technicians, and specialized tools to every project. Our team delivers high-quality, efficient overhauls with minimal downtime, ensuring your TEG operates like new.

How often should I have my TEG overhauled or cleaned?

Overhaul frequency depends on operating conditions, but we recommend a full inspection and service annually. If your TEG is under heavy use or exposed to harsh environments, more frequent maintenance may be necessary.

What happens if I neglect regular overhauls?

Ignoring maintenance can lead to reduced efficiency, overheating, equipment failure, or even total system shutdown — all of which can result in costly downtime and repairs.

What signs indicate my TEG needs servicing?

Watch for:

Decreased output performance

Unusual noises or vibrations

Visible leaks or excessive soot buildup

Increases in system temperature or pressure

Unpleasant odors during operation

How long does a typical overhaul and cleanout take?

A complete TEG overhaul typically takes 2–3 days, depending on the system’s condition and size. CROFT’s team prioritizes quality while minimizing your operational disruption.

Can my system stay operational during the overhaul?

No. For safety and quality assurance, the TEG must be shut down during service. We work quickly to restore operations as soon as possible.If interested in one of CROFT's mobile units, please don't hesitate to reach out to one of our service technicians for more information.

What services are included in a CROFT overhaul?

Our comprehensive overhaul services include:

Full disassembly and industrial cleaning

- Glycol purge to remove residual water to reduce start up time

Leak detection and repair

Component replacement as needed

Calibration and performance testing

Final safety inspection and certification

How do I schedule an overhaul with CROFT?

Contact us via phone, email, or through our website. Our customer service team will guide you through scheduling, assessments, and next steps to get your TEG back to peak performance.

Features & Benefits

Resources

Gallery

If you are looking for production or processing equipment for your well site, an Account Manager will be in touch with you within one business day.