I’m pretty confident that the majority of people in society know what fracking is by now. Whether they have a positive or negative stance on fracking is a whole ‘nother can of worms.

The basic principals of fracking goes all the way back to the 1950’s. However, the technology of horizontal drilling has made fracking the darling of the oil and gas industry in the 21st century. So reading that companies are trying to save money by re-fracking existing wells is kind of made me have that ‘well duh’ moment.

The definition of re-fracking is just like it sounds. Companies can revisit older, previously drilled wells and use newer or really just more effective technology to stimulate production of the well. To frack a brand new well, it can cost upwards of 8 million dollars from drill to completion. However, re-fracking can only cost a company 2 million. Pretty nice saving, especially in this market.

That is really the biggest factor to the growing interest of re-fracking, the current market.

Below is a quote from an June article written by Sharon Kelly for DESMOGBLOG.com

“In terms of the market potential, I think you’re talking billions in terms of revenue opportunities over an extended period of time.” Schlumberger CEO Paal Kibsgaard told investors during a quarterly conference call this year. “In terms of how many wells, I would say there are thousands of wells in North America land that are candidates for refracturing, and this is both shale liquids and shale gas.”

Everyone in the oil and gas industry is really paying attention to the news, reading publications and listening to conversations about the current market. There are so many different opinions out there on when the market will bounce back, and it will. Some of them make me laugh, especially when they come from people who know nothing about about the industry. But you know what they say about opinions………

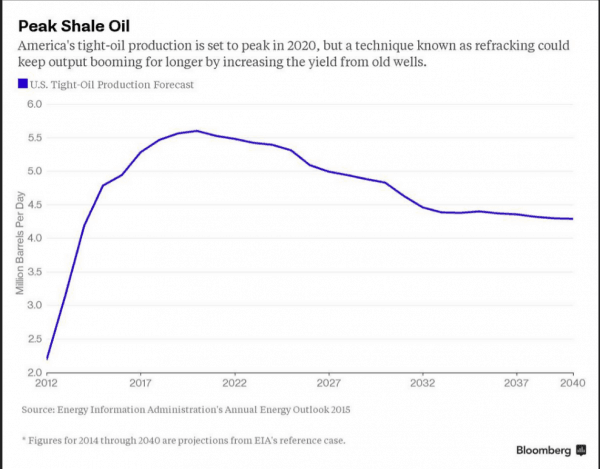

So if you see that production is growing but the new well count has not moved, re-fracking could be the reason.

Croft Production Systems specializes in customized natural gas processing equipment. Our main product line includes six units that can help optimize your well site and save your company money. We now have a generator and compressor unit line. These pieces of equipment can process natural gas on-site and allow your well site to run on that by-product natural gas. Thus saving your company money by fueling well site equipment.

References:

http://www.desmogblog.com/2015/06/04/will-re-fracking-be-shale-drilling-industry-s-next-big-move