Glycol Sampling Analysis Program

Triethylene Glycol Dehydration (TEG) units not being properly maintained could cost operators 10s of thousands of dollars. The costs of not servicing TEG units with professionals could have liquid carryovers, extra wear and tear on components, decreased dehydration capability, and premature chemical degradation.

Croft offers a glycol analysis program to give our clients insight into what is working and what is not working in the dehydrator. This lab-analyzed sample is broken down into components and then reviewed by CROFT's engineering team to give recommendations where necessary to get the unit back on track.

Our Glycol Analysis Program Includes:

- Boxed container for sample jars

- Sample jars

- Step-by-step instructions

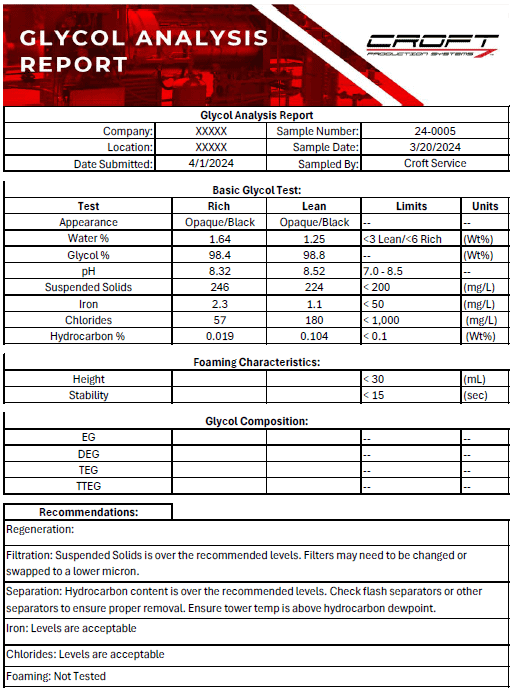

- Full glycol analysis report with engineering recommendations for optimal performance

Order your glycol Sampling Kits or Schedule a call to get on the program

Contact a sales representative to set up a call to get on a regular program that fits your operation schedule.

Frequently Asked Questions:

What is the Glycol Analysis Program?

Our Glycol Analysis Program provides regular testing and assessment of the glycol used in natural gas dehydration systems. The goal is to ensure optimal performance, minimize corrosion, and extend the lifespan of your equipment.

Why is glycol quality important?

Poor-quality glycol can lead to operational issues such as foaming, corrosion, freezing, and reduced dehydration efficiency. Monitoring and maintaining glycol health protects your assets and prevents costly downtime.

How often is glycol analysis performed?

We recommend monthly sampling as a standard, but frequency can be adjusted based on system performance, environmental conditions, or operational changes.

What does the analysis include?

We test for:

pH level

Specific gravity

Clarity and color

Presence of hydrocarbons

Salt content

Degradation byproducts (e.g., organic acids)

Will I receive recommendations?

Yes. Along with a detailed lab report, you’ll receive tailored recommendations for improving glycol condition—whether it’s filtration, reprocessing, or replacement.

How do I participate in the program?

You can enroll by contacting our operations team or submitting a request through our client portal. Once registered, we’ll coordinate sample collection and reporting.

What are the sample requirements?

Samples should be taken from clean, representative locations using approved containers. We can provide guidance or assist with on-site sampling if needed.

Is there a cost for this service?

For clients on a service agreement, glycol analysis is typically included. For others, a small fee may apply. Please contact us for pricing details.

What happens if glycol issues are found?

We’ll work with your operations team to implement corrective actions and avoid potential system failures, ensuring continued compliance and reliability.

Example Glycol Analysis Report

Features & Benefits

Resources

Gallery

If you are looking for production or processing equipment for your well site, an Account Manager will be in touch with you within one business day.