Cameron P. Croft

Founder and CEO

Mr. Croft graduated from the University of Houston with a Bachelor of Science in Mechanical Engineering Technology and holds a Master of Science in Technology Project Management with a black belt in Lean Six Sigma. Since 2006, Mr. Croft has served as the founder/CEO of several other natural gas processing companies including Croft Production Systems and Croft Supply. In 2019, Mr. Croft established the Surplus Energy Equipment with a team of engineers that have been in the oil and natural gas industry for over 10 years. He designed this platform to allow clients to see a full line of equipment without having to make phone calls to vendors or spend time searching for quality equipment. His focus now is building relationships with partners and expanding on CROFT's product lines.

Find me LinkedIn: https://www.linkedin.com/in/cameron-p-croft/

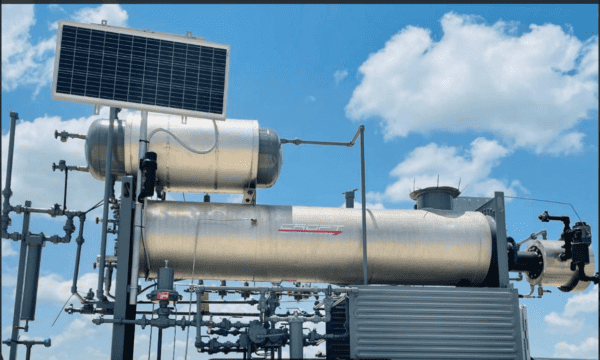

Introduction Today we’re at a natural gas dehydration unit, often called a glycol system. Now these systems are used to dehydrate the natural gas by removing the water vapor that’s present in the natural gas to reduce corrosion and prevent hydrate formation. Now the way this system works is the gas will enter through the […]

Introduction Today we’re at a natural gas dehydration unit, often called a glycol system. Now these systems are used to dehydrate the natural gas by removing the water vapor that’s present in the natural gas to reduce corrosion and prevent hydrate formation. Now the way this system works is the gas will enter through the […]

In the world of natural gas midstream and upstream operations, hydrogen sulfide (H2S) is a constant adversary. Left untreated, it corrodes infrastructure, poses severe health risks, and prevents gas from meeting pipeline quality specifications. Among the various desulfurization technologies available, Iron Oxide Systems (IOS)—often referred to as “iron sponge” or “solid bed scavengers”—remain a gold […]

An amine plant, also known as an amine treating unit or gas sweetening unit, is a critical component in the oil and gas industry, designed to remove acidic components—primarily hydrogen sulfide H2S and carbon dioxide CO2 —from natural gas and other process streams. This process is essential for meeting pipeline specifications, protecting equipment from corrosion, […]

Industrial burners sit at the center of many oil and gas processing operations. From glycol dehydration units and amine plants to line heaters and fired process heaters, safe and efficient combustion is critical to production reliability, operating costs, and personnel safety. Yet burners are often treated as “set it and forget it” equipment. Over time, […]

Complete Glycol Dehydration System Maintenance from Inspection to Startup Triethylene Glycol (TEG) dehydration systems are mission-critical assets in natural gas processing. When a TEG unit underperforms, the consequences are immediate—off-spec gas, excessive glycol losses, foaming, corrosion, and unplanned shutdowns. That’s why professional TEG cleanout and overhaul services are essential for operators seeking reliable dehydration performance […]

Case Study Blog: How Chlorides Affect Glycol Dehydrators in Natural Gas Processing Glycol dehydration units are critical in the natural gas industry for removing water vapor from raw gas streams to meet pipeline and sales gas specifications. Among the many contaminants and operational challenges that glycol dehydrators face, chlorides (e.g., NaCl, CaCl₂, MgCl₂) stand out […]

The Due Diligence Deep Dive: Top 10 Questions to Ask Before Buying a Glycol Dehydrator In the world of natural gas processing, removing water vapor is not just a regulatory requirement—it’s a fundamental necessity for preventing corrosion, inhibiting the formation of dangerous gas hydrates, and ensuring the gas meets pipeline quality specifications typically 7 pounds […]

The Due Diligence Deep Dive: Top 10 Questions to Ask Before Buying a JT Plant In the upstream and midstream sectors of the oil and gas industry, efficiency, recovery, and regulatory compliance are the cornerstones of profitability. A Joule-Thomson (JT) Plant—a simple, elegant piece of technology leveraging the cooling effect of gas expansion—is often the […]

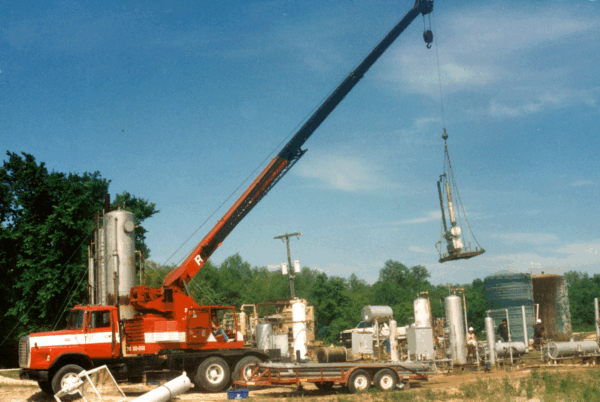

Preston Croft was raised in a hardworking family in South Texas in the 1950s. Surrounded by people who valued both effort and humor, he learned the importance of perseverance early on. His father and grandfather spent their careers in the oil and gas industry. Growing up with limited means, Preston learned to appreciate and take […]

Removing water moisture from natural gas is critical to ensure safe transportation and processing in oil and gas processing. One of the most widely used technologies for this purpose is the glycol dehydrator, typically utilizing Tri-ethylene Glycol (TEG) to absorb water vapor. Like all equipment exposed to harsh operating environments, glycol dehydrators require periodic cleaning […]

The transition from reactive maintenance to proactive preventative service has become a game-changer in the oil and gas industry. It’s not merely a shift; it’s a strategic move that safeguards against failures, minimizes downtime, and maximizes production efficiency, ultimately translating into enhanced profitability. At Croft Production Systems, we understand preventative maintenance’s pivotal role in natural […]

Natural gas, a vital energy source for various industries, often requires careful treatment before being transported and utilized efficiently. Dehydration is a critical process in preparing natural gas for distribution. This post delves into the fascinating world of Tri-ethylene Glycol (TEG) systems, a standard method for natural gas dehydration. We explore the importance of this […]

Hydrogen Sulfide (H2S) is a highly toxic gas that poses severe risks to personnel and can cause numerous issues throughout the oil and gas production process. To address the detrimental effects of H2S, it is crucial to remove this gas efficiently. Croft Production Systems offers two effective solutions for H2S removal: their Amine Plant (GSS) […]

Needville, Texas, May 23, 2023 – Croft Production, a leading energy equipment, and solutions provider, is pleased to announce its portfolio expansion and diversification with the introduction of advanced technologies for drilling and eFracking gas units. These innovative solutions help operators save on operational costs while promoting environmental sustainability. The drilling industry is constantly seeking […]

Acid gas is a type of natural gas that contains significant quantities of hydrogen sulfide (H2S), carbon dioxide (CO2), or similar acidic gasses.

As I learned more about natural gas, I started to be curious about where it all started. How did we even find natural gas? How did we know what it could be used for? Natural gas is essential and used daily for things such as heating, stove tops, water heaters, etc. I thought it would […]

This virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

This virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

As the push for sustainable energy is becoming increasingly renowned, companies are taking stock in how they can contribute to its demands, leading to a rise in renewable natural gas.