Understanding Hydraulic Fracturing: Demystifying Concerns

As we delve deeper into the intricacies of the energy industry, it’s sometimes essential to return to fundamental concepts. While discussions often revolve around regulations, pipeline logistics, and post-wellhead gas treatment, a prevalent inquiry remains centered around hydraulic fracturing, colloquially known as “fracking.” This piece aims to elucidate the process, alleviating uncertainties and concerns.

What is Fracking?

Hydraulic fracturing, commonly known as “fracking,” stands at the forefront of modern energy extraction methods, particularly in the pursuit of natural gas and oil reserves. But what precisely does this process entail, and how does it fit within the larger scope of drilling and energy operations?

Breaking Down the Process

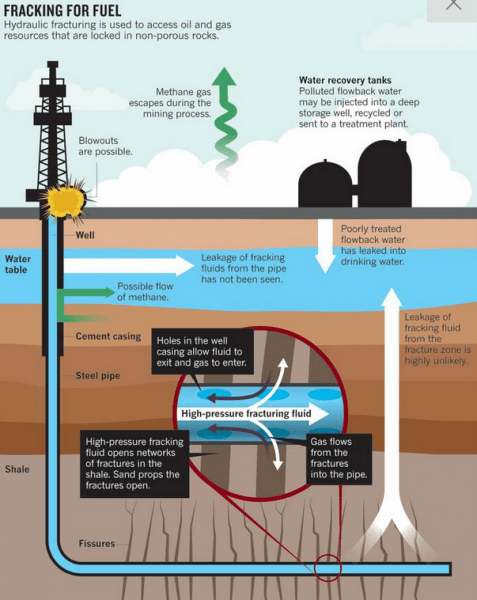

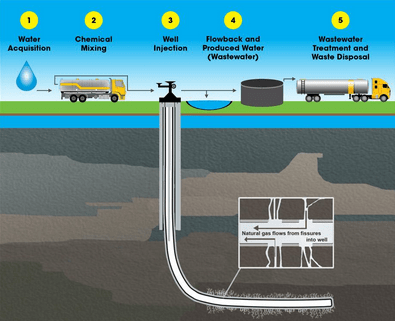

At its core, hydraulic fracturing is the art and science of accessing hydrocarbon-rich layers deep beneath the Earth’s surface. The technique is predicated on the creation of small fractures in subsurface rock formations, primarily shale. This is achieved by introducing a specially formulated fluid under immense pressure. This fluid is a meticulously engineered mixture, predominantly made up of water, which acts as the base, combined with sand and a selection of specific chemicals.

- Water: Serving as the primary fluid, water acts as the driving force, facilitating the application of high pressures to break the rock.

- Sand: Sand particles, once the rock is fractured, intrude into these tiny spaces and act as a propping agent. This ensures that the newly formed pathways remain open, allowing oil or gas to flow freely.

- Chemicals: These are added for a range of reasons, from reducing friction (which improves the efficacy of the process) to inhibiting the growth of microbes that might obstruct the flow of the extracted materials.

Fracking in the Energy Landscape

When considering the broader spectrum of drilling and energy extraction, hydraulic fracturing has revolutionized the industry. Traditional drilling methods often only access oil or gas pools, but fracking allows us to tap into vast reserves trapped in rock formations. By creating and maintaining these micro-pathways in the rock, previously inaccessible or uneconomical reserves can now be extracted. This has not only expanded the potential lifespan of many oil and gas fields but has also opened up entirely new regions for exploration and extraction.

In summary, hydraulic fracturing, with its combination of engineering precision and geological expertise, has redefined the boundaries of the energy industry. While it’s a single technique within a vast repertoire of drilling methods, its impact on the landscape of energy extraction is both profound and transformative.

The Drilling Process: Building a Strong Foundation

Hydraulic fracturing begins with an essential foundational step: creating the well bore. This process, while seemingly straightforward, encompasses meticulous engineering efforts designed to ensure both the efficiency of extraction and the protection of the environment. Here’s a deeper exploration of this phase in hydraulic fracturing:

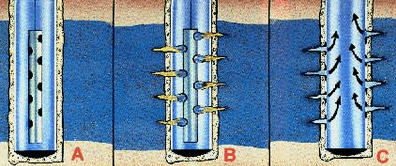

1. Well Bore Creation: The initial drilling phase carries out a pathway deep into the earth, reaching down to the targeted oil or natural gas reserves. This vertical shaft, known as the well bore, is the main conduit through which extracted resources will flow later.

2. Strengthening with Steel: Once the well bore is drilled, fortifying its structure is crucial. Here, a steel pipe, often referred to as casing, is introduced. The choice of steel, known for its strength and resilience, ensures that the well bore remains robust against the immense pressures and stresses it will encounter, both from the extraction process and the surrounding geology.

3. The Importance of the Annulus: The annulus, which is the gap existing between the well bore’s walls and the newly inserted steel casing, plays a pivotal role in the well’s structural and environmental integrity. It’s a space that requires careful attention to prevent any potential breaches or leakages.

4. Cementing for Protection: The annulus is sealed with cement to safeguard the surrounding environment, especially the precious freshwater aquifers lying closer to the earth’s surface. This acts as a formidable barrier against any potential contaminants that might attempt to migrate from the well bore. Moreover, the cement provides additional structural reinforcement, anchoring the steel casing in place.

5. Layered Defense: In hydraulic fracturing, redundancy is a virtue, especially when it pertains to environmental protection. The cementing process isn’t just a single layer; it’s reiterated at least seven times. This multi-layered approach ensures that even if one layer were to fail, several others remain as backups, offering multiple levels of protection against potential contamination.

Visualizing the Protective Structure: Imagine peeling back the layers of the earth like an onion. You’ll eventually reach the well bore as you delve deeper, past the freshwater aquifers and through various geological strata. Now, picture this well bore ensconced in multiple concentric rings of steel and cement. This imagery provides a tangible sense of the robust protective measures designed to keep the extraction process isolated from the surrounding environment, particularly the critical aquifers.

In essence, the infrastructure underpinning hydraulic fracturing isn’t just about effective resource extraction; it’s equally about safeguarding the environment. It’s a balanced dance between engineering innovation and environmental stewardship.

The Transition to Fracking

With a foundational understanding of the initial drilling procedures, let’s segue into the heart of hydraulic fracturing. A highly recommended video by Marathon Oil lucidly illustrates and details the drilling and fracking processes.

A “perforating gun” is introduced into the drilled well during fracking. This tool is then activated using an electric impulse, releasing bullets that puncture the shale rock layer. Subsequently, a “proppant” is introduced to widen and maintain the newly formed fractures in the shale.

Comprising 99% sand and water, the proppant plays a pivotal role in the extraction process. It enables the gas and fluid trapped within the shale to be released, facilitating its upward movement through the well. For a more tangible understanding, imagine observing a proppant extracted from an actual well site. Once cleaned and dried, this granulated substance essentially resembles common sand.

Fracking in Perspective

From well establishment to the commencement of gas flow, fracking remains integral. Despite recent criticisms, an in-depth exploration of the process can enlighten one about the meticulous procedures and safeguards in place. The advent of hydraulic fracturing has indeed transformed gas extraction. It enables the retrieval of gas from challenging shale deposits previously deemed inaccessible. As the industry advances, companies remain committed to safeguarding aquifers, minimizing environmental impact, and efficiently harnessing the vital gas resources society heavily relies on.