What is a Glycol Dehydration Unit?

Triethylene glycol (TEG) unit or glycol dehydrator is a liquid desiccant system used for the removal of water from natural gas and NGLs. It is the most commonly used means of water removal from natural gas. A TEG Unit also referred to as a glycol unit, uses absorption, which occurs when the water vapor is taken out by a dehydrating agent, or liquid desiccant.

A TEG unit removes water vapor from the gas or liquids such as natural gas or oil. Water vapor in gas is like humidity in the air; it can only be removed through a dehydration process such as a liquid or solid desiccant dehydrator or with refrigeration. Water vapor is the amount of water contained in gas at a given temperature and pressure. There are three main characteristics that affect the water vapor in gas; temperature, pressure, and volume.

With higher temperatures, the more water vapor the gas can hold. For every 20°F, the water vapor capacity will double which means more desiccant will be needed to remove the water vapor. It is crucial that water vapor is removed from the natural gas stream because it can cause corrosion within the gas lines and equipment. Hydrates can also form, clogging pipelines, valves, and transport equipment.

Here at CROFT, we like to first find out what the volume, temperature and pressure is, so we can determine how much water vapor needs to be removed and what size equipment will be needed to appropriately dehydrate the gas.

There are different types of dehydration products, but this blog will focus specifically on glycol dehydration units which are a non-regenerative system utilizing liquid glycol absorbents to hydrate the gas.

Components that make up a Glycol Dehydration Unit:

There are several components on a TEG unit that are critical to the function or can greatly improve the efficiency of the system. We partner with Surplus Energy Equipment to provide our clients with components to repair or upgrade their existing Tglycol dehy unit. These components are available as-is or for re-certification.

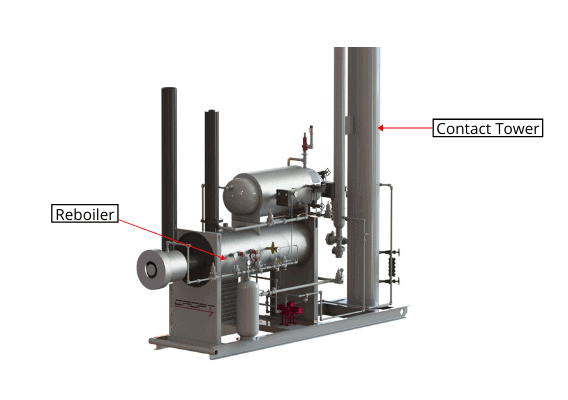

- Reboilers– Reboilers drive the water from the wet desiccant into the atmosphere. Reboilers, also referred to as regenerators are either direct-fired or steam-heated with a stripping column on top. Stripping columns can be packed or contain trays. Reboilers are often fueled by fuel gas from the gas stream of the contractor. In this case, the fuel gas quality may need to be improved using a fuel gas conditioning system.

- Contact Towers– The contact tower, or gas contactor can be packed or tray columns. The wet gas passes upward through the column, water vapor is absorbed by the glycol and the gas becomes progressively drier.

- BTEX Units– BTEX units are heat exchangers used to capture and recycle BTEX and V.O.C. from the regenerator still column. Having a BTEX unit reduces operating costs and by recovering sellable concentrates and using VOC vapors for burner fuels.

How a Glycol Dehydrator works:

We discussed some of the components a TEG, but keep reading for a better understanding of how those components work together to achieve the overall function.

- Wet gas enters the inlet scrubber, which is placed before the contact tower to remove any free water, dust, condensed hydrocarbons, and other impurities

- After going through the separator, the wet gas enters through the contact tower where it rises through the column. As its rises through the contact tower the gas meets the lean glycol solution flowing downward across either bubble trays, random packed or structured packed towers

- Next, the rich TEG exchanges heat with the lean TEG and enters the still column. The TEG then flows downward through the still column to the reboiler where it is heated around 375°F and removes all but a small percentage of the water from the regenerator

- The hot, dry glycol then flows through an overflow system to the surge section of the reboiler, where the glycol pump then pulls lean TEG and pumps the glycol back into the top of the contact tower, where the drying process is repeated

Croft Production Systems, Inc. has developed a glycol dehydration design that combines the best practices through the industry. CROFT will properly size and sell a system to meet your needs. For efficiency gains and environmental consideration, CROFT promotes this baseline product with upgraded features like BTEX, Burner Management Systems (BMS), and sensors with control kills.

Read more about TEG units.

Shop for TEG parts.

Shop for used or surplus components for TEG units.