Why use a filter?

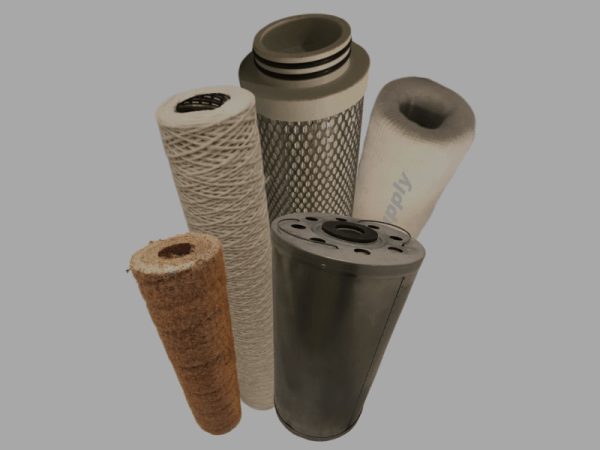

The filter removes common contaminants such as water, glycols, amines, hydrocarbon liquids, oils, rigid solids, semi-solids, and foams. They are an instrumental part in maintaining the systems for natural gas processing. Many consequences can be created by lack of filtration, such as foaming issues in a regenerative system which could cause fouling and carryover.

How can hydrocarbons be removed with amine filters or glycol filters?

Due to carryover with the incoming gas or condensation in the absorber, liquid hydrocarbons increase glycol/amine foaming, degradation, and losses. They must be removed with a glycol-gas separator and/or activated carbon filters. Properly sizing these filters to handle total flow is critical because once they start to meet capacity, back pressure may start to increase on the system.

How can sludge be removed with glycol filters or amine filters?

An accumulation of solid particles and heavy hydrocarbons very often forms in the glycol/amine systems. Before the gas enters the system, it will be prudent to add a coalescing filter before the unit to remove as much as contaminants as possible. The emulsions or tarry oils will begin to settle out, accumulating into a sludge, causing fouling of pumps and interconnecting piping or in the reboiler, causing heating issues. A good solution is a properly sized filtration system pre and post-pump filter, activated carbon filtration, and a preventative maintenance schedule that changes these filters out.

What do you need to size a filter for natural gas application?

- The maximum flow

- The minimum operating pressure

- The maximum temperature

- The gas composition

- The contaminate you are trying to remove in the system

What do you need to size a filter for liquid application?

- The maximum flow rate of the liquid

- The contaminate you are trying to remove in the system.

- The operating temperature

- The composition

- The viscosity of the liquid

What gaskets are needed for filter housings?

- The buna is the go-to gasket for lower-temperature glycol and hydrocarbon services

- Viton is often satisfactory for amine service as the gasket on the element.

- Teflon is preferred for amine but can be a harder material to seal

Why do you need activated carbon filtration?

Activated carbon filters remove liquid hydrocarbons, surfactants, well-treating chemicals, compressor lube oils, etc. from a glycol side stream.

What is the difference between Filter Separator vs. Coalescer?

Filter separators are designed for heavy particulate removal and mildcoalescing. Coalescing filters are designed to coalesce mist or aerosols from the gas and separate them. They can handle light to medium particulates.

Learn more about CROFT Joule Thomson Systems or Request a Quote.