The calendar officially states that we are in winter. However, seeing people while having lunch out of the office in tank tops and flip flops contradicts that for those of us who are in south Texas… 70 degree days and 40 degree nights, in December, is nothing out of the ordinary for us. For people who live in parts of the world that do have a true winter, we are going to discuss something that can be very detrimental: hydrate formation. Now, you don’t necessarily have to have cold weather for hydrate formation, but it sure does help expedite up the process.

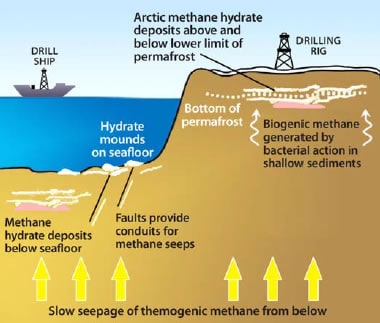

The infographic below shows the basic parameters for hydrate formation, but let’s learn more about the subject. Before I go on any further I want to get rid of any confusion. This blog is not about methane hydrate “ice” deposits that are formed underground. Nope, no conversations about Arctic permafrost or Antarctic ice. Well, maybe another time.

What is the Definition of a Hydrate?

Back to the main subject: The definition of a hydrate is a compound, typically a crystalline one, in which water molecules are chemically bound to another compound or element. In a nutshell, hydrates are a crystal looking formation made up of water and gas molecules. They are formed when these two elements (water and gas) are combined with high pressure and low temperatures. Once the hydrate is formed they will continue to build upon one another to create a huge build up and even complete blockage of a line.

What issues do hydrates cause?

Hydrate formations can slow down the flow of oil and gas through a pipeline. They can even block pipelines altogether. That means a production slow down.

Hydrates can also be dangerous and costly as they cause pressure to build up, whic can ultimately lead to fires or explosions.

How are hydrates prevented?

So, we know the basics on how hydrates are formed. Below are some different ways companies try to prevent hydrate formations. Keep in mind companies often use more than one method at a time.

- Dehydration- Removing any water from the oil or gas stream by use of a drying agent. We all know that water will freeze at 32* Fahrenheit. So cold liquid and then freezing temperatures outdoors, the inevitable will happen.

- Temperature Control- Small gas-fired heating units are typically installed along the gathering pipe or where ever it is likely that hydrates will form. Good ‘ole insulation of pipelines or insulated boxes to cover units can be used to keep equipment warm too.

- Chemical Inhibitors- Injecting chemicals like methanol into the oil or gas stream while still in liquid form will change the molecular make up of the liquid in the pipeline, thus preventing formations.

- Pressure Control- Installing Joule Thomson valves will cause pressure drop once the liquid has passed through it. However the temperature will drop to, so now we are back to temperature control.

All the methods I listed above to prevent hydrate formation, CROFT can help you with. The six units in our main production line are specifically designed to help our clients process natural gas in the field. We know that cold weather can be detrimental to pipelines and machinery. So, let us help you not have a slow down during the colder months. We can winterize any of our units as well! Our Passive Dehydration System (PDS) will dehydrate your natural gas stream with no moving parts, no flaring, and no air permits are required. Our Fuel-Gas Conditioning System (FCS) will remove gas heavies to prevent freeze-ups of fuel lines, clean gas for for fuel and instrumentation. Lastly, our Chemical Injection System (CIS) improves chemical efficiency with atomization methods and static mixers.