Removing water moisture from natural gas is critical to ensure safe transportation and processing in oil and gas processing. One of the most widely used technologies for this purpose is the glycol dehydrator, typically utilizing Tri-ethylene Glycol (TEG) to absorb water vapor. Like all equipment exposed to harsh operating environments, glycol dehydrators require periodic cleaning and flushing to maintain optimal efficiency and prevent costly damage. This essay outlines the detailed procedures for cleaning and flushing a glycol dehydrator, emphasizing safety protocols, step-by-step practices, and best maintenance strategies to promote system longevity and environmental compliance.

Understanding the Glycol Dehydrator System

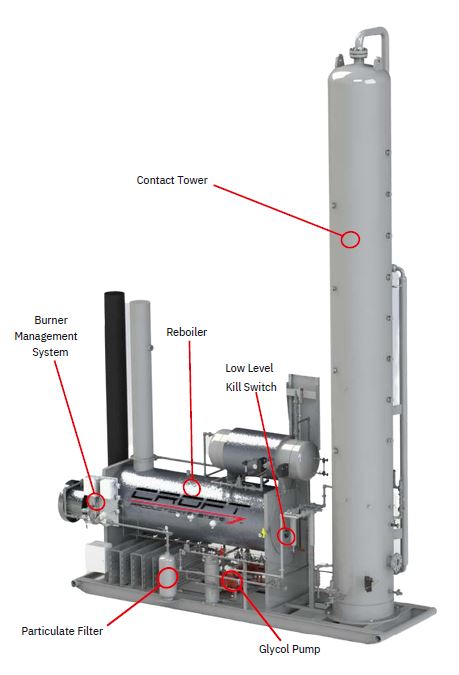

A glycol dehydrator consists of several key components that work together to remove water from natural gas:

- Contactor Tower – Where wet gas flows upward through a packed bed, contacting downward-flowing lean glycol.

- Reboiler – Heats glycol to evaporate water and regenerate it.

- Flash Tank – Removes light hydrocarbons and gases from the rich glycol.

- Filters and Strainers – Remove solids and oil to maintain glycol quality.

- Circulation Pumps – Move glycol throughout the system.

Over time, contaminants such as hydrocarbon liquids, salts, corrosion by-products, and solids can accumulate, reducing dehydration efficiency and causing fouling or corrosion.

Safety Precautions

Cleaning and flushing operations carry inherent risks, especially in systems that have processed flammable natural gas. CROFT technicians on the crew have gone through countless hours of training and risk management to comply with all internal safety precautions and client governing bodies like PECSafeland, Veriforce, and ISNetworld. The following safety steps are some of the essential steps:

- PPE (Personal Protective Equipment) – Flame-resistant clothing, gloves, goggles, and possibly respiratory protection.

- Lockout/Tagout (LOTO) – Securing all energy sources to prevent accidental startup.

- Gas Detection – Monitoring for flammable gases.

- Ventilation and Purging – Using inert gases (e.g., nitrogen) to vent the system safely.

Strict adherence to safety protocols helps prevent injuries, fires, or explosions.

Preparation for Cleaning

Cleaning begins with a safe system shutdown. Below are some of the steps CROFT conducts in this procedure:

- Isolate the glycol system from the gas stream.

- Depressurize all vessels.

- Allow the system to cool to ambient temperature.

- Drain glycol into appropriate containers for analysis, reuse, or disposal.

Inspect internal surfaces for fouling, stress cracking, corrosion, or sludge buildup and document the condition of all components. CROFT Technicians will take pictures and videos of this step, which are included in the service tickets. Any escalated issues will be brought to the client’s attention for remediation recommendations.

Flushing Procedure

Once drained, flushing is carried out using:

- Hot water

- Methanol

- Commercial glycol system flush products

Steps include:

- Fill the system with the flushing fluid.

- Circulating the fluid through all components, including reboiler, contactor, and piping.

- Cleaning or replacing filters and strainers.

- Running multiple flush cycles as needed.

- Draining and drying the system completely with air or nitrogen.

Glycol Quality Monitoring

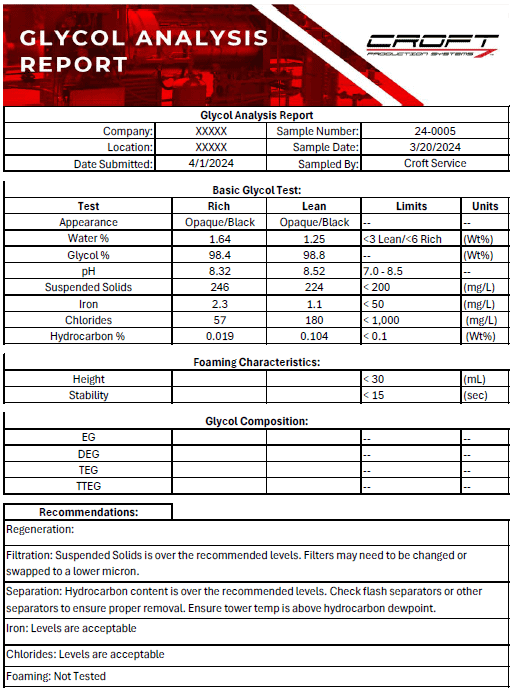

Before recharging, CROFT technicians test glycol for:

- Water content – Should be under 2%.

- pH – Typically between 7 and 9.

- Clarity and color – No solids or discoloration.

- Hydrocarbon contamination – Should be negligible.

Use lab analysis or portable testing kits. Poor-quality glycol should be discarded or sent for reclamation.

Recharging and Restarting the Glycol Dehydrator System

Steps to restart the system:

- Refill the system with clean, filtered glycol.

- Inspect all fittings and valves for leaks.

- Conduct pressure testing (usually with nitrogen).

- Slowly bring the reboiler to operating temperature.

- Gradually reintroduce gas flow while monitoring system performance.

Monitor TEG circulation rate, outlet gas moisture content, and reboiler operation.

Environmental Disposal Practices

Fluids and debris generated during flushing and draining must be disposed of responsibly:

- Store in labeled, approved containers.

- Use certified waste disposal services.

- Keep disposal records and manifests.

- Prevent spills with secondary containment systems.

Case Study: Poor Maintenance Consequences

In 2022, a dehydrator in West Texas failed due to neglected maintenance. The reboiler was severely fouled, and TEG purity dropped below 90%, causing pipeline hydrate formation. The result: full system replacement costing over $240,000.

Routine flushing and filter changes could have prevented this failure—an expensive lesson on the value of regular maintenance.

Preventative Maintenance Tips

To reduce cleaning frequency and avoid breakdowns:

- Change filters every 1–3 months.

- Inspect reboiler burners or heating elements regularly.

- Sample glycol monthly.

- Check for corrosion or leaks.

- Maintain a detailed maintenance log.

A structured schedule ensures better performance and system reliability.

Conclusion

Cleaning and flushing a glycol dehydrator is an essential maintenance task to preserve the efficiency and safety of natural gas processing operations. From shutdown, flushing, and glycol recharging to environmental compliance and preventative maintenance, each step contributes to a more reliable and cost-effective operation. Regular upkeep not only prevents costly repairs but also promotes a safer work environment and helps operators meet regulatory expectations. A clean glycol dehydrator is a productive one—keeping gas dry, operations smooth, and costs down.