With the oil and gas industry taking a hit right now you have not heard too much complaining from fracking haters. Production has slowed so there are less wells being fracked, so I guess that means less complaining.

Speaking of complaining. An interesting document was released this week. An independent group of subject matter experts from academia, industry, federal agencies, and environmental organizations came together to research the issue of seismic activity related to oil and gas development. People have been shouting that fracking is to blame. Come to find out, it is not. It is actually a wastewater injection that is the issue. The main problem is that most people have no idea what the differences between the two processes are.

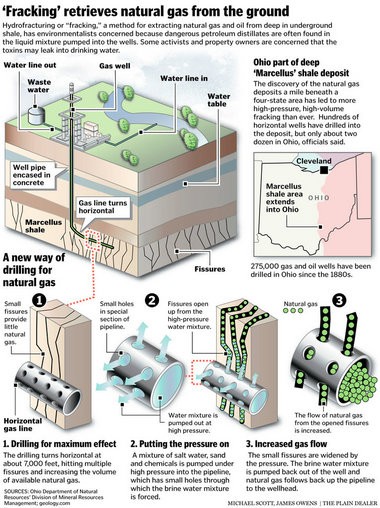

Here is a quick definition of fracking from my fellow CROFT blogger, Jessica Lee. “By simple definition, fracking is a technique used when drilling for natural gas and oil. It is a technique where rock below the surface is fractured open by pressurized liquid made up of sand, water, and chemicals.”

That defined process is what people think is causing seismic activity because of what it does. It literally (and I hate using that word) fractures the shale formations so that the natural resource can be drawn out. People naturally assume because the formation is now broken up that, the ground is unstable, and seismic activity will happen more frequently. A Stanford University geophysicist named Mark Zoback made an interesting analogy. He stated that fracturing will “affect a very small volume of rock and release, on average, about the same amount of energy as a gallon of milk falling off a kitchen counter.”

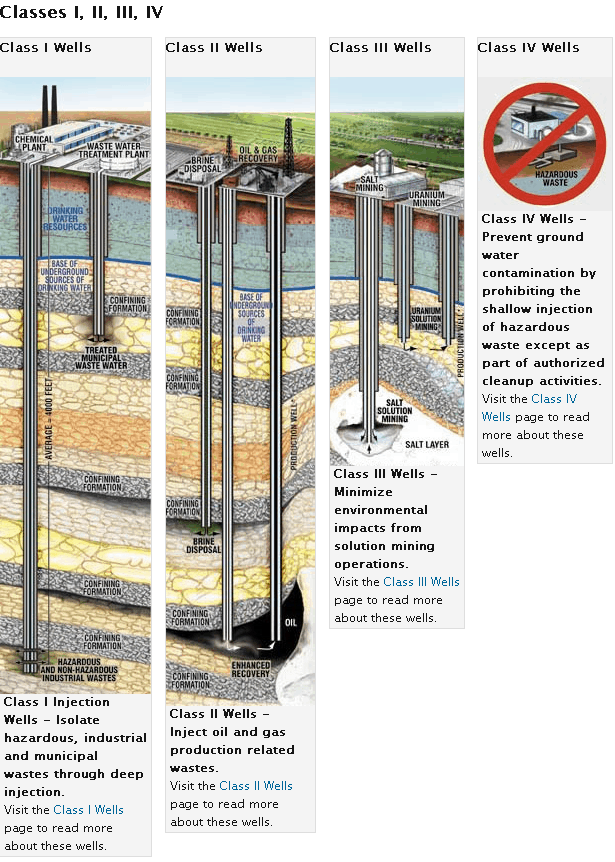

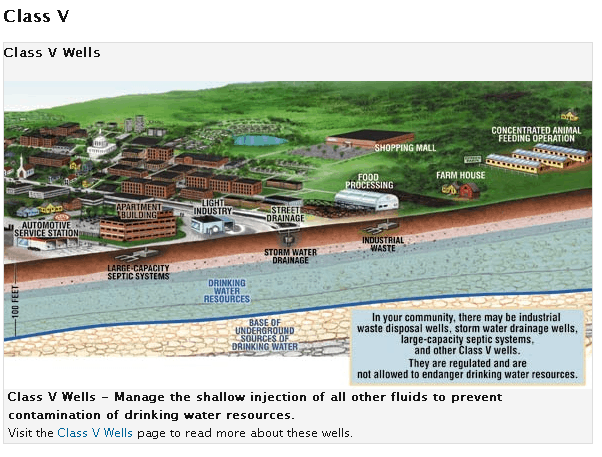

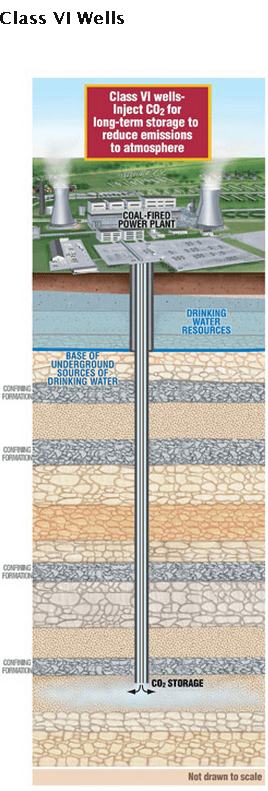

So where is the activity coming from? It is coming from Waste Water Injection or Waste Water Disposal. They are one in the same. The Environmental Protection Agency or EPA, defines wastewater wells as such: “An Injection well is a device that places fluid deep underground into porous rock formations, such as sandstone or limestone, or into or below the shallow soil layer. These fluids may be water, wastewater, brine (salt water), or water mixed with chemicals.

The chart above shows that the EPA has six different classifications of wastewater wells. The classification all depends on how deep the well is, what is stored in the well, and what industry is utilizing the well.

Once again, you need to have a perspective on the situation. The EPA states that there are hundreds of thousands wastewater injection wells around the United States. Of those, 168,000 are considered Class II, oil & gas related.

Below are drawing of each of the different well classes.

After lots of reading what I have learned is that the reason the wastewater wells have more of an issue is that the well is ongoing. When a well is fracked, it is not a continuous process. The fracking process is usually completed in a few days. However, the wastewater injection well is continuously being used during the entire project it is paired with.

So yes, we may be splitting hairs, but get it right, people. It is not fracking that causes the quakes, it may be one of the steps that come with fracking a well, but it is not the fracking process. Yes, you do have to dispose of the water used during the fracking process. However, it is not always with a wastewater well. Sometimes companies truck the water out. In warmer, dryer parts of the country, some use an open-air pond and try to get the water to evaporate. Companies are also trying to find ways to recycle the frack water.

Believe it or not, there are people in the oil and gas industry trying their best to be green while drilling for natural resources.

Croft Production Systems is one of those companies. Our Passive Dehydration System (PDS) is so environmentally friendly your company will not even need an air permit for the unit. Click the link below to learn more about our green unit.

http://media.wix.com/ugd/d3e01e_7a12408392f240c89943d3f500039004.pdf

http://blog.cleveland.com/metro/2011/05/fracking_fluid_being_treated_a.html

http://www.what-is-fracking.com/does-hydraulic-fracturing-cause-earthquakes/

http://water.epa.gov/type/groundwater/uic/

http://water.epa.gov/type/groundwater/uic/basicinformation.cfm#what_is

https://www.usgs.gov/natural-hazards/earthquake-hazards/induced-earthquakes