As the push for sustainable energy is becoming increasingly renowned, companies are taking stock in how they can contribute to its demands. How do we become more energy independent? How can we decrease our emissions and carbon footprint? How can we progress to meet the sustainable industry needs? The renewable natural gas charge takes on all these questions and contributes to solutions for a sustainable future.

The Challenge of Renewable Natural Gas

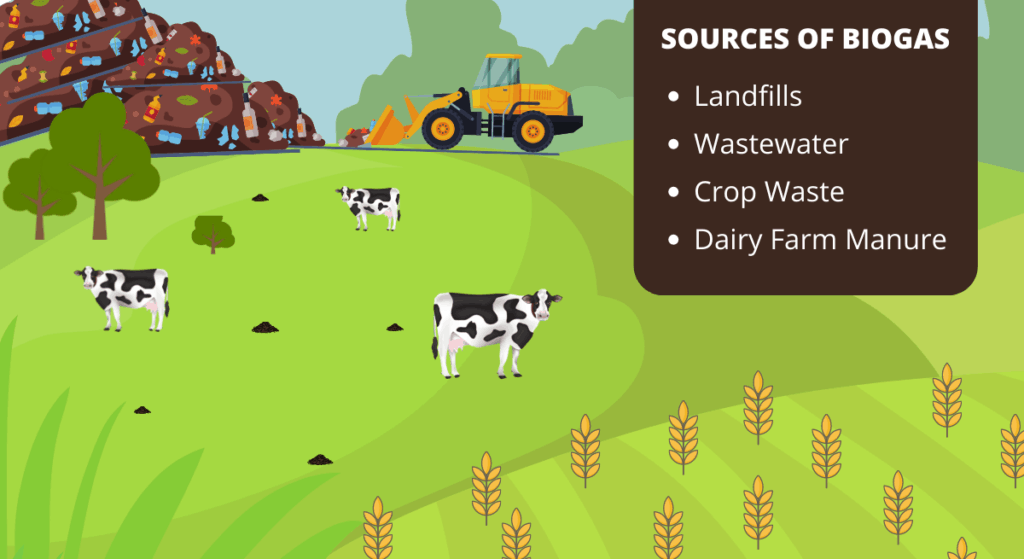

As modern society becomes predominantly industrialized in everyday applications it results in insurmountable wastes and increased emissions. These wastes create biogas containing carbon dioxide that is introduced into the atmosphere. Some research theorizes that this gas in the air will change the Earth’s climate and make our world hotter.

We capture biogas from organic wastes in landfills, manure from dairy farms, wastewater, and crop wastes. Biogas is primarily methane and carbon dioxide with trace amounts of other gases. We look to capture this gas before it enters the atmosphere and furthermore, upgrade it to create a cleaner-burning, sustainable fuel.

The Benefits of Renewable Natural Gas

In the current effort to decrease carbon footprint and create a world thriving on renewable energy resources, there are many ways to benefit from RNG production. Aside from providing gas to homes and vehicles, other benefits include:

- Capture emissions of unused “waste” methane. Lower greenhouse gas emissions.

- Reduce the need for conventional fuel

- Energy independence

- Revenue source for farmers

- Cut production and waste disposal costs

- Not an intermittent renewable source. The energy does not depend on the sun shining or wind blowing.

- Government subsidies

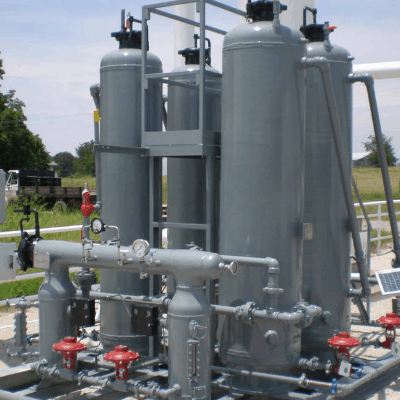

Creating and Processing renewable Natural Gas

The wastes are directed to digesters where they are covered. This both stops biogas from escaping into the air, as well as, creates an environment lacking oxygen to promote production – anaerobic digestion. We collect the biogas from digesters and separate water, acid gas i.e. H2S and Co2, and dehydrate it. We are left with biomethane. A cleaner burning, chemically identical gas to fossil fuel that can be injected into gas pipelines. Here at CROFT, we offer solutions for acid gas removal and dehydration.

The Gas Sweetening System, GSS, also known as Amine gas treating, refers to the process of removing H2S And CO2 (hydrogen sulfide and carbon dioxide) from natural gas. Carbon dioxide and hydrogen sulfide are often found in raw biogas. CO2, when combined with water, will create carbonic acid which is corrosive. H2S is an extremely toxic gas that is very corrosive to equipment and must be removed.

CROFT offers Iron Oxide Systems, which utilize one of the most common methods of gas sweetening, utilizing a chemical reaction process using iron oxide media in a contact vessel for H2S removal in gas streams. This unit offers excellent removal of H2S and other mercaptans and works well with varying volumes and H2S levels in biogas.

Passive Dehydration System (PDS): CROFT’s preferred dehydration unit is our Passive Dehydration System, which is a solid desiccant dehydrator that is safe, easy, and effective in dehydrating the gas stream utilizing the adsorption process.

A glycol dehydration unit is comprised of two major components: the contact tower, and the regeneration skid. Gas enters the bottom of the contact tower, also known as an absorber. At the same time, lean glycol is pumped into the top of the tower. The gas contacts the glycol through special internals in the tower to facilitate the absorption of the water vapor.

Learn more about CROFT’s solutions for processing renewable natural gas.