Gas dehydration is the removal of water from the gas stream in order to meet pipeline specifications. In addition to separating oil and some condensate from the wet gas stream, it is necessary to remove most of the associated water. Most of the liquid, free water associated with extracted natural gas, is collected by oil and gas separators at or near the wellhead. However, additional water vapor removal is often needed with a dehydration unit in order to get the gas quality to meet the pipeline standards.

Why is Dehydrating Natural Gas Important?

Natural gas must be dehydrated to remove water vapor. Water vapor causes the formation of hydrates, over saturation of natural gas, and corrosion of equipment. Hydrates are solid, ice-like crystallized compounds formed of hydrocarbons and water. Hydrate formation occurs in high-pressure well streams with a low temperature. Hydrates can form, however, at temperatures above the freezing point. The high pressure increases saturation and creates more water vapor. Hydrates cause freezing and blocking of pipelines, valves, and other equipment, bringing production to a halt. Oversaturated gas does not meet pipeline specifications of 7 pounds per mmcfd, which must be removed in order to sell. The temperature and pressure determine whether water is in a gaseous state or has condensed into a liquid. When in liquid form, water also causes corrosion to equipment. In order to prevent these harmful effects, gas is dehydrated by being condensed from vapor into liquid form and then removed by either adsorption or absorption.

Dehydration Techniques:

1. Glycol Dehydration: liquid chemical system used for the removal of water from natural gas and NGLs. It is the most commonly used system, also known as a TEG unit.

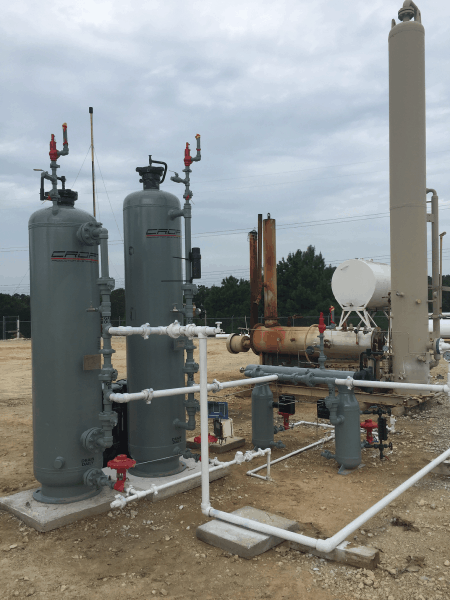

2. Desiccant Dehydration: Hygroscopic substance that induces or sustains a state of dryness. It is the safest and most eco-friendly option. CROFT uses this form of dehydration with the Passive Dehydration System, also known as a PDS unit.

Dehydration Process

1. Absorption: occurs when the water vapor is taken out by a dehydrating agent. This is the type of dehydration is used by Glycol units. CROFT’s TEG uses this process to dehydrate natural gas.

2. Adsorption: occurs when the water vapor is condensed and collected on the surface. CROFT’s PDS uses this process to dehydrate natural gas.

TEG Vs. PDS

Triethylene glycol (TEG): There are several safety issues incurred with the use of a TEG unit. Unlike the PDS, the TEG unit is a complex system with multiple moving parts, open flames, safety hazards, and toxic emissions. TEG’s multiple moving parts and hazardous open flames require constant supervision and maintenance. Safety hazards result from high gas velocities and poor mist eliminators which cause glycol carryover, excessive re-boiler temperatures causing thermal decomposition and vaporization of glycol, and increasing temperatures which create salt deposits, while corrosion occurs when glycol reacts with sulfur. TEG units also emit several billion cubic feet of toxins annually. Emissions include hazardous air pollutants (HAP’s), volatile organic compounds (VOC’s) which are highly flammable, and BTEX which consists of benzene, toluene, ethylbenzene and xylenes, which are lethal carcinogens.

While CROFT encourages our Passive Dehydration Systems as a safe, environmentally-friendly alternative to a TEG, TEGs do have advantages that make them a more viable option in certain circumstances. They are able to create a lower pressure drop of 5-10 psi vs. a dry desiccant unit would be between 10-15 psi. Glycol units are regenerative vs. dry desiccant units are non-regenerative and the desiccant does need to be disposed of. TEGs are the most common choice for dehydration units across the industy. CROFT offers a TEG design that combines optional design choices throughout the industry to be as operator-friendly as possible, therefore reducing safety risks and improving efficiency.

Passive Dehydration System (PDS): The safe alternative to TEG units have no moving parts or open flames, and zero emissions. Due to the increased safety and unit’s simplicity, minimal maintenance is required for the PDS unit. There are no permit requirements for the PDS unit, unlike the TEG units with increasingly stringent regulations. The countless hazards that come with the use of a TEG unit make PDS units a unanimous solution to safe natural gas dehydration.

Environmental Considerations

TEG units emit both air and ground pollutants. Several known VOC’s, volatile organic compounds, such as propane, benzene and formaldehyde occur in natural gas and are emitted from TEG units. VOC’s can cause eye, nose and throat irritation, and even damage to your liver, kidney and central nervous system. Triethylene glycol, the chemical used in TEG units, is also used in anti-freeze and brake fluid. Triethylene glycol spills kill any living organisms. TEG units also emit HAPs, hazardous air pollutants, which cause or may cause cancer and other serious health effects, including birth defects, and adverse environmental and ecological effects. BTEX, or benzene, toluene, ethyl benzene and xylenes are carcinogens and are also emitted from TEG units. According to a study done by the U.S. Department of Health and Human Services, all four components of BTEX can produce neurological impairment. In addition, benzene can cause hematological effects which may lead to plastic anemia and the development of acute myelogenous leukemia.

The annual methane emissions from dehydrators alone are over 12 billion cubic feet, which is equivalent to 4.8 million tons of carbon dioxide, or 933,000 car emissions. One TEG unit emits an average of 4,562 Mcf/year of methane, being equivalent to 354 cars emissions. The EPA states a reduction in methane by 99% using a desiccant dehydrator, or PDS unit, over a glycol dehydrator. Croft’s PDS has an annual release of 23.34 Mcf/year of methane, or 0.002 cars annually. Unlike the TEG unit, all waste in a PDS unit is condensed into a non-hazardous brine solution and safely disposed of. The PDS unit allows for the conservation of natural resources, a reduction in environmental and health liabilities, eliminates permitting for air emissions, and the emissions themselves while complying with all state and federal environmental regulations. The environmental aspect alone is enough to convert from a TEG unit to PDS. the HAP’s, VOC’s and BTEX emitted from TEG units, an outrageous amount of methane is also emitted. According to the EPA, methane has a 21 times greater greenhouse effect than carbon dioxide.

Learn more about the CROFT Passive Dehydration System.

*Content updated May 2020 by Croft Representative