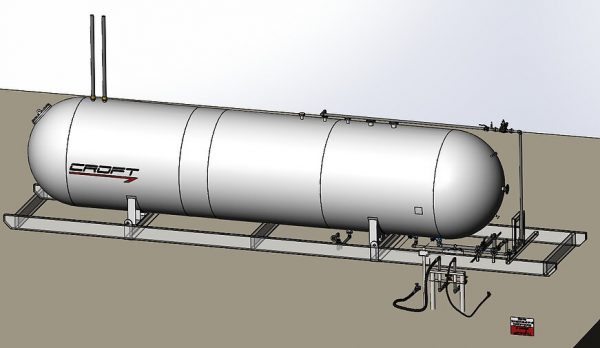

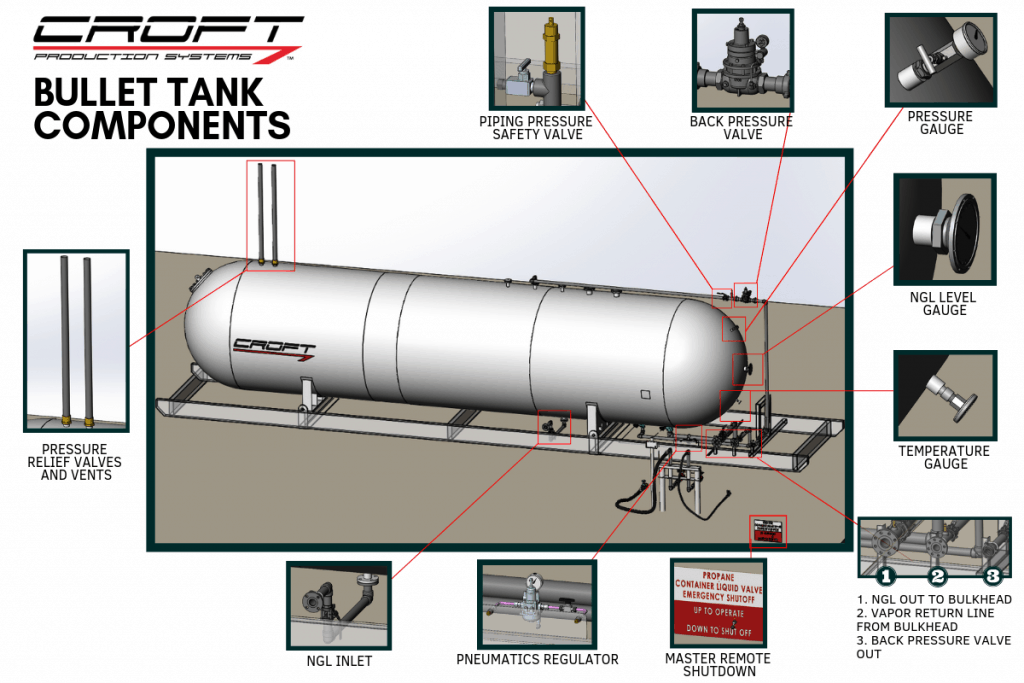

There are many guidelines that our industry must follow to ensure there is a safe environment for everyone. At CROFT, we follow the same standard and safety guidelines for all of our equipment and bullet tanks are no exception.

Last week we told you what a bullet tank was and what it is used for. Today, we are discussing the various safety features on a bullet tank.

- Bulkhead

- Smart Transfer Hose

- Bullet Tank PSV

- Piping PSV

- Break Away Points on the Bulkhead

- Pneumatics

- Internal Valves Heat Melt Fittings

- Master Shutdown/Bulkhead Switch

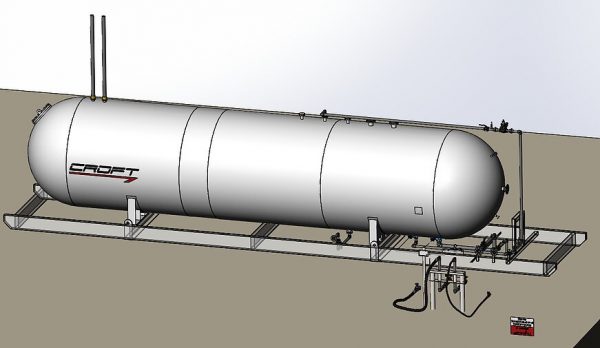

BULKHEAD AND SMART TRANSFER HOSE

The bulkhead is cemented into the ground using a cement 4 x 4 x 4 foot block. This cement block will protect the interconnecting piping in the unlikely case that a truck was to forget to unhook the transfer hoses and drive away.

The smart transfer hose connects the unloading truck to the bulkhead and bullet tank unloading piping. Located inside the smart transfer hose is a line wire that runs from one end to the other connecting the check flaps on each end. In failure mode, this hose is stretched by the drive off, therefore closing both ends sealing the NGL tank and truck.

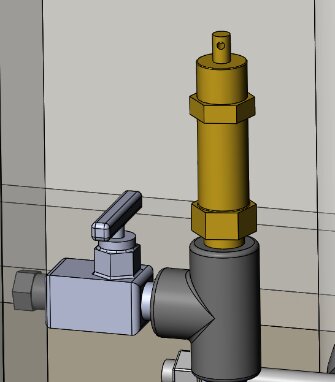

PIPING PRESSURE SAFETY VALVES AND BULLET TANK PRESSURE RELIEF VALVES

The pressure relief valves will prevent any damage due to over pressuring the vessel beyond what it is designed to handle.

When NG’s are isolated throughout the piping they experience Higher temperature fluctuations, as the temperature increases the pressure increases. The PSVs are installed in areas where the NGLs are isolated due to those temperature fluctuations.

If the pressure was to exceed 350 psi on the piping PSV, the relief valves will open and vent out the excess pressure through the pressure relief valves and vents located on top of the bullet tank.

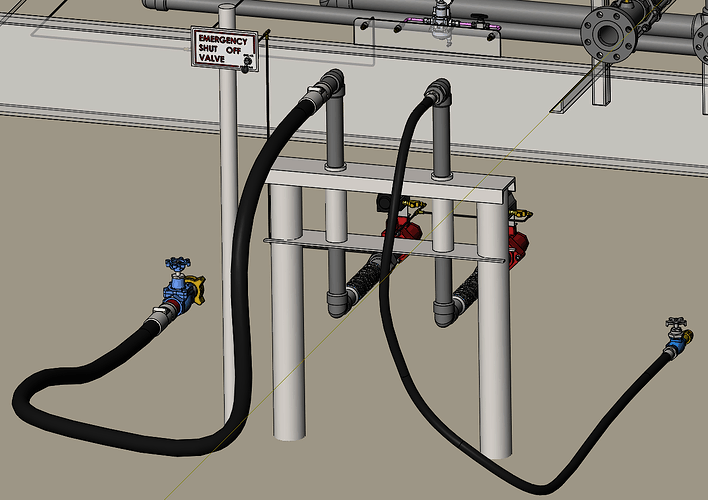

BREAKAWAY POINTS ON BULKHEAD

In the case of breakaway failure, there is the breakaway point that is located on the bulkhead. The break away point is the nipple coming out of the bulkhead. It is designed to shear off in the case of a drive off. The nipple must be 12 inches or longer in order to properly shear off during a failure case

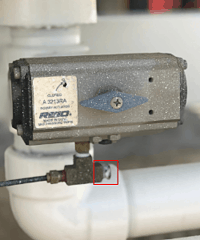

PNEUMATICS AND INTERNAL HEAT MELT FITTING

In case of failure, there is the pneumatic safety feature. All valves are fail close, meaning that if anything were to fail (leaks, tears, kinks, etc in the tubing) the pneumatic pressure would vent out, therefore closing all valves.

In case of a fire, the fitting will melt releasing the pressure in the pneumatic lines closing all the valves.

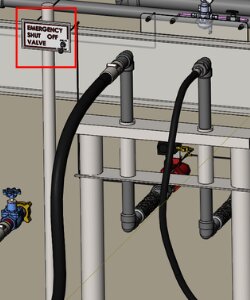

BULKHEAD SWITCH

In case of failure, there is the master shutdown and bulkhead switch. The bulkhead switch is located on the bulkhead for the driver who is removing the liquids from the tank. The driver will hook up to the bulkhead and then turn on the switch, opening a pathway for the NGLs to fill the tank. In the event of an emergency or after completion, the driver can flip the switch to off, immediately sealing off the tank.

MASTER SHUTDOWN

The master shutdown switch is a minimum of 25 feet away and a maximum of 100 feet away from the bulkhead, in the direction of the egress. If the bulkhead switch is not convenient to shut down and there is an emergency, the driver or operator can exit towards the master shutdown and immediately flip the switch, shutting off all the valves.

If you are interested in learning more or you want a quote on bullet tanks, please request a quote.