Natural gas is a hydrocarbon gas mixture primarily composed of methane but can also include small amounts of other gasses like ethane, propane, and butane. This fossil fuel forms over millions of years through the compression and heating of plants and animal remains buried underground. It is found in underground rock formations, and its extraction process can be complex.

As a vital energy source for households and industries worldwide, natural gas is preferred for power generation due to its lower carbon dioxide emissions than coal and oil. In this article, we will explore natural gas production, encompassing the steps from exploration and extraction to transportation and distribution.

What is Natural Gas?

Plants and animals absorbed solar energy through carbon molecules millions of years ago. Over time, these organisms died and sank to the ocean floor. Buried under layers of sand, silt, and rock, they underwent immense heat and pressure for millions of years, transforming into natural gas.

This gas, primarily composed of methane, is called “natural” gas due to its creation from natural elements. It also contains natural gas liquids (NGL) and non-hydrocarbon gasses like carbon dioxide. Natural gas produces carbon dioxide, water vapor, and nitrogen oxides when burned. While colorless and odorless, a distinct scent is added to aid in leak detection.

Natural Gas Uses

Natural gas is useful in various sectors, making it an indispensable resource. Primarily, it is extensively used for residential and industrial heating purposes, as well as for electricity generation. Additionally, natural gas is fuel for vehicles and a crucial raw material for manufacturing fertilizers and other chemical processes.

In the United States, the three main uses are:

Manufacturing

Natural gas assumes a pivotal role in the oil and gas industry, particularly in the domains of steel and paper production, where it is employed to generate process steam to facilitate diverse industrial applications. Furthermore, natural gas serves as a fundamental component in the petrochemical sector, contributing to the manufacturing of essential products such as plastics, fertilizers, synthetic fibers, cosmetics, and medicines. The versatile utilization of natural gas in these industries underscores its significant value and underscores its status as a vital resource in the production of a wide range of essential materials.

Electricity Generation

The use of natural gas for electricity generation is prevalent, particularly in regions lacking access to renewable energy sources like hydro, wind, and solar power. This market continues to expand as countries and regions strive to reduce carbon emissions.

Industrial Use

Natural gas serves as both a fuel and a feedstock in numerous industries. It is used for fuel purposes and as a raw material for manufacturing chemicals, fertilizers, and other products. Currently, the industrial sector accounts for approximately one-third of total natural gas consumption in the United States. Natural gas constitutes around one-third of the energy consumed by the industrial sector.

Heating

The most prevalent application of natural gas is for heating purposes. Natural gas is favored for heating due to its extended burn time, low comparative costs, and dependable nature. In North America and other parts of the world, homes, apartment complexes, office towers, and other buildings are directly connected to natural gas pipelines, enabling a reliable and continuous energy supply.

Transportation

It is often overlooked by the general populace that natural gas has served as a fuel source for vehicles since the 1930s. Presently, an impressive fleet of over 150,000 vehicles traverses the roads of the United States, with a global count exceeding 5 million, all operating on natural gas. The utilization of natural gas as a fuel for buses and trucks is rapidly gaining traction, with projections indicating a significant surge in numbers. The adoption of natural gas in the transportation sector plays a pivotal role in curbing detrimental emissions, leading to a notable reduction in smog pollution levels.

Where, and How, are We Sourcing Our Natural Gas?

Natural gas is typically found in underground rock formations known as reservoirs, which contain small cavities that trap and retain water, natural gas, and oil. When natural gas is trapped beneath a reservoir, it remains there until extraction takes place. Conventional natural gas is extracted by drilling wells. However, unconventional natural gases like shale gas, tight gas, and gas hydrates require different extraction techniques such as horizontal drilling and hydraulic fracking.

Once extracted, the natural gas is transported through pipelines to processing plants, where hydrocarbons and fluids are separated from the gas. Subsequently, the purified gas is either sent back through the pipelines to distribution centers or stored for future use.

Natural Gas Processing

Natural-gas processing is a sophisticated industrial procedure meticulously designed to purify raw natural gas, effectively separating impurities, non-methane hydrocarbons, and fluids to produce high-quality dry natural gas suitable for pipeline transmission.

The process of treating natural gas commences at the wellhead. The composition of raw natural gas extracted from producing wells varies based on factors such as the type, depth, and location of the underground deposit, as well as the geological characteristics of the region. It is worth noting that oil and natural gas are frequently found together in the same reservoir.

Natural gas obtained from oil wells is typically referred to as associated-dissolved gas, indicating its association with or dissolution in crude oil. Conversely, natural gas production not linked to crude oil extraction is classified as “non-associated” or “free gas.”

Extracting & Transporting Natural Gas

In natural gas extraction, conventional deposits allow for a relatively easy upward gas flow through wells. However, natural gas production from unconventional sources has gained prominence, particularly in the United States and other countries. This involves extracting gas from shale and sedimentary rock formations through hydraulic fracturing or fracking. Unconventional or tight gas, as it is known, is often found in deep underground reservoirs, such as shale rock or coalbed methane. Technological advancements have improved extraction techniques to access these challenging deposits. Once extracted, the transportation of natural gas presents various challenges. This is where liquefied natural gas (LNG) becomes significant.

By cooling natural gas to a shallow temperature of -250ºF (-160ºC), it transforms into a clear liquid state, making it easier to store and ship. The liquefied gas is transported through pipelines to reach tanker ships and cargo trains, which haul it to end users. Several countries, including Qatar, Iran, Canada, and the United States, engage in the production, export, and utilization of natural gas in its liquefied form to facilitate efficient transportation and distribution.

Exploration of Natural Gas

The first step in the production of natural gas is the exploration of potential natural gas reserves. This process involves the use of various techniques to locate areas where natural gas may be found. Some of the common techniques used for natural gas exploration include seismic surveys, magnetic surveys, and gravity surveys.

Drilling for Natural Gas

Once a potential natural gas reserve is identified, the next step is to drill a well to extract the gas. The drilling process involves the use of a drill rig that is equipped with a drill bit. The drill bit is used to create a hole in the ground, which is lined with steel or plastic pipe to prevent collapse.

Completion of a Gas Well

After a well is drilled, it is completed to allow for the production of natural gas. The completion process involves the use of specialized equipment and techniques to ensure that the well can produce gas at a sustainable rate. This may involve the use of hydraulic fracturing, or fracking, which involves the injection of water, sand, and chemicals into the well to create small fractures in the rock formation and allow gas to flow more freely.

Production of Natural Gas

Once a well is completed, the process of natural gas production begins. This involves the use of various techniques to extract the gas from the rock formation and bring it to the surface. Some of the common techniques used for natural gas production include vertical drilling, horizontal drilling, and multi-stage fracturing.

The Five Steps of Natural Gas Processing

After the natural gas is produced, it must be processed to remove impurities and other unwanted components. The processing of natural gas involves the use of various techniques, such as dehydration, compression, and sweetening, to ensure that the gas meets the required quality standards.

Oil & Condensate Removal

The initial step in natural gas processing is separating gas from oil, which takes place in equipment near the wellhead. The specific process employed depends on factors such as the composition of the gas, well location, and separation requirements. When natural gas is dissolved in oil under underground pressure, separation can be relatively straightforward, often accomplished using an essential piece of equipment known as a “conventional separator.”

This equipment comprises a tank where gravity assists in separating the oil, causing it to settle at the bottom while the gas rises to the top for extraction. However, in more complex scenarios, natural gas processing plants employ sophisticated equipment tailored to specific circumstances. For instance, when a well produces high-pressure gas alongside light crude oil, specialized equipment like Low-Temperature Separators (LTXs) come into play. LTX operates by cooling the gas through heat exchangers, causing it to expand and subsequently undergo a pressure drop. This process results in the condensation of liquids, facilitating the separation of the natural gas in a dry state.

Carbon Dioxide and Sulfur Removal

When natural gas contains hydrogen sulfide (H2S), it is called sour gas. In such cases, a sweetening process is necessary to eliminate the H2S. This process involves passing the gas through a tower containing an amine solution that absorbs the sulfur, similar to the glycol dehydration process.

The removal of sulfur is essential due to safety concerns, as hydrogen sulfide can be harmful and even lethal. Also, sulfur contributes to corrosion, posing risks to pipeline and compression systems. Once extracted, the gas processing company can sell the sulfur as a valuable by-product.

Another undesirable component in natural gas is carbon dioxide. It leads to pipeline corrosion, increases compression costs, and reduces the heating value of the gas. Natural gas processing plants employ various technologies to remove carbon dioxide, including cryogenic distillation, membranes, and amine absorption. These techniques help ensure the gas meets quality standards and minimize adverse effects during transportation and usage.

Sweetening

After removing water, condensates, and oil from natural gas, it becomes necessary to eliminate any traces of hydrogen sulfide and carbon dioxide as well. This particular stage of the process is commonly referred to as “sweetening” the gas, owing to the pungent and unpleasant odor associated with sulfur. It is a crucial step because hydrogen sulfide is not only corrosive but also highly toxic.

While the National Agency of Corrosion Engineers (NACE International) establishes product specifications and regulations to mitigate the effects of sulfur, the Occupational Safety and Health Administration (OSHA) mandates the implementation of additional preventive measures.

Dehydration

Water vapor in natural gas can lead to issues such as hydrate formation, oversaturation, and corrosion, which can negatively impact pipelines and equipment. To address this, natural gas processing plants employ two standard techniques: glycol dehydration and solid-desiccant dehydration.

Glycol Dehydration: An organic compound called glycol is used as a liquid desiccant to remove water from the natural gas in glycol dehydration. The process involves passing the wet gas through diethylene glycol (DEG) or trimethylene glycol (TEG) using a device known as a “contactor.” The glycol desiccant absorbs the water vapor, causing the heavier water particles to settle at the bottom of the contactor. The water solution is extracted, leaving the gas dry and ready for further processing.

Solid-Desiccant Dehydration: Solid-desiccant dehydration is often a more effective method. It entails passing the gas through two or more adsorption towers, typically filled with solid desiccants such as activated alumina or granular silica gel. The solid desiccant materials absorb most of the water content in the gas as it flows from the top to the bottom of the towers. As a result, the gas exits the process at the bottom of the tower in a dry state, suitable for subsequent processing stages.

Both glycol and solid-desiccant dehydration are essential in natural gas processing plants to effectively remove water vapor, ensuring the gas meets quality standards and mitigating potential issues related to hydrate formation, over saturation, and corrosion.

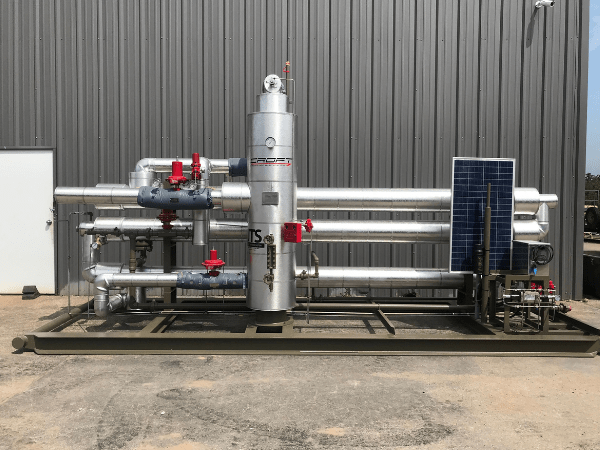

Croft Production Systems, Inc., has an innovative and environmentally-friendly solution for natural gas dehydration – The Passive Dehydration System (PDS). Our solid desiccant dehydrator offers a safe, efficient, cost-effective method tailored to your specific requirements. The PDS provides three benefits. First, it offers an economical solution, saving time and expenses typically associated with obtaining air permits. Our dehydrator preserves your gas stream, eliminates emissions, and optimizes cost-efficiency.

Second, the PDS is an environmentally conscious choice, as it boasts zero operational emissions. Unlike glycol dehydrators, which release methane, volatile organic compounds (VOCs), and hazardous air pollutants (HAPs) into the atmosphere, our system prioritizes sustainability. Lastly, safety is paramount, and our dry desiccant dehydration units feature no moving parts or open flames, ensuring a secure operating environment.

NGL Extraction

Natural gas liquids (NGL) treatment typically involves separation and fractionation to obtain the base components. The separation of NGLs is commonly carried out in a centralized processing plant using lean oil absorption and cryogenic natural gas processing. Lean oil absorption and cryogenic natural gas processing aim to produce methane as the primary product, which is marketed as natural gas.

The secondary goal is to extract valuable components such as ethane, propane, butanes, and natural gasoline. In the adsorption technique for NGLs separation, similar to dehydration, the gas is passed through an adsorption tower where a desiccant material, such as lean oil, separates the NGLs, allowing them to settle at the bottom. The extracted NGLs are then separated from the gas, leaving it free of liquid hydrocarbons.

Cryogenic natural gas processing involves lowering the temperature to -120 degrees Fahrenheit (-84°C) using external refrigerants and an expansion turbine. This method is particularly effective for extracting lighter hydrocarbons like ethane. The gas stream is first chilled with external refrigeration and then passed through the expansion turbine, causing the pressure to drop.

As a result, ethane and other lighter hydrocarbons condense while methane remains in the gaseous state. Ethane, with its high value for the petrochemical industry in plastic production, is recovered efficiently, with the cryogenic process typically achieving 90 to 95% recovery. Another advantage of cryogenic natural gas processing is the generation of energy. The energy produced from the expansion turbine can be utilized to recompress the gas stream, reducing operating costs.

Maximizing the value of natural gas liquids (NGLs) often entails selling their components separately, making an investment in a fractionation process economically favorable. Once the separation process is complete, the resulting product must be fractionated to separate it into its base components. This is achieved by gradually heating the NGL stream in multiple stages, causing the hydrocarbons to boil off one by one based on their distinct boiling points.

The fractionation process involves specialized fractionators designed to separate a specific hydrocarbon. The fractionators are named after the hydrocarbon they are intended to separate. The process begins with euthanization, separating ethane from the NGL stream.

It then proceeds to the depropanizer, which isolates propane. Finally, the debutante separates specific butanes while leaving pentanes and heavier hydrocarbons in the NGL stream. Subjecting the NGL stream to fractionation makes obtaining individual components with higher market value possible.

This approach allows for more efficient utilization of each hydrocarbon and contributes to the overall economic viability of the natural gas liquids industry.

NGL Recovery

The process of extracting natural gas liquids (NGLs) from natural gas is called NGL recovery. The quantity of NGLs present is typically measured in gallons per 1,000 cubic feet (gpm). A 1-2 GPM indicates a “lean” or dry composition, while a measurement exceeding four GPM is considered “very rich” or wet.

The initial step in NGL recovery involves completely removing NGLs from the natural gas stream. This can be achieved using a system such as Croft’s JTS (Joule-Thomson System), which effectively eliminates heavy hydrocarbons and hydrates. The vapor is transformed into a liquid state by cooling the gas temperature, making it easier to remove.

The demand for a JT (Joule-Thomson) unit increases with higher NGL richness, and it also reduces the gross heating value while removing hydrates. Once the NGLs have been extracted, they undergo a process known as fractionation, separating them into individual products. Fractionation enhances the value of the NGLs and provides flexibility in their utilization.

The equipment used for this separation process, which separates components like ethane, propane, butane, and pentanes based on their volatility, is called a fractionator train. This enables the production of specific NGL products with higher market worth, offering various applications in different industries.

Transportation of Natural Gas

Once the natural gas has been processed, it is transported through pipelines to various distribution points. The transportation of natural gas requires the use of specialized pipelines that are designed to transport the gas safely and efficiently over long distances

Environmental Impacts of Natural Gas

The environmental impact of natural gas has gained significant attention amidst the climate crisis. Natural gas is a relatively cleaner and cost-effective energy source than coal and petroleum products. Its combustion emits lower levels of carbon dioxide, which is advantageous. However, it is crucial to consider alternative energy options.

It is worth noting that natural gas, primarily composed of methane, can escape into the atmosphere during drilling, storage, and transportation processes. Methane, a potent greenhouse gas, contributes significantly to global warming and environmental degradation, approximately 34 times more powerful than carbon dioxide. The immediate environmental concerns associated with natural gas revolve around the drilling process.

Natural gas drilling can disturb fragile ecosystems, generate air pollution, and cause extensive land destruction. Additionally, the extraction and processing of natural gas can result in water contamination. Another issue is the environmental impact of natural gas flaring. In certain situations, natural gas is burned or flared at the well site when it is not economically viable to transport and sell.

This flaring process releases harmful compounds like carbon dioxide, carbon monoxide, and sulfur dioxide into the atmosphere. There is ongoing debate regarding the reliance on natural gas as a transition away from coal, with many advocating for a shift towards purely renewable energy sources such as solar and wind power to address the climate crisis effectively.

Growing Natural Gas Production

According to the US Energy Information Administration (EIA), natural gas production in the United States has displayed a general upward trend over the past decade, albeit with occasional fluctuations. In 2020, US dry natural gas production amounted to approximately 33.4 trillion cubic feet. While this represented a slight decrease compared to the preceding year, it remained one of the highest recorded levels.

The significant growth in natural gas production in the US can be attributed to advancements in drilling technologies, such as hydraulic fracturing (fracking), which have unlocked vast shale gas reserves. This has led to a surge in production from regions such as the Marcellus and Utica shale formations, primarily located in the northeastern and Appalachian areas of the country.

The abundant supply of natural gas in the US has profoundly impacted various sectors of the economy. It has contributed to the country’s energy security, reduced dependence on imported fuels, and provided a cleaner-burning alternative to coal for electricity generation. Additionally, abundant and affordable natural gas has attracted investment in industries that utilize it as a feedstock, including petrochemicals and manufacturing.

While there may be year-to-year fluctuations in natural gas production, the overall upward trajectory highlights the continued importance of natural gas in the energy landscape of the United States. As the nation strives to balance energy needs, environmental concerns, and the transition to cleaner sources, natural gas remains significant in shaping the country’s energy future.

Natural Gas and Green Initiatives

In pursuing a clean energy transition, natural gas holds immense potential in the years ahead. The industry has made notable strides in reducing carbon and methane emissions associated with natural gas production. Simultaneously, constructing and operating an increasing number of LNG export facilities facilitate the global mobility of U.S. natural gas production.

While specific clean energy sources like solar and wind may require an extended period to reach widespread adoption, low-carbon natural gas has the potential to make a more immediate impact on transitioning to cleaner energy alternatives.

Partner with Croft Production Systems Today

In conclusion, natural gas processing and production play pivotal roles in meeting the energy demands of our modern world. Croft Production Systems, Inc. stands as a trusted partner in providing top-quality production and processing equipment for well sites. With our extensive expertise and commitment to excellence, we ensure efficient and safe operations that optimize gas recovery and minimize environmental impact.

To explore our comprehensive range of equipment and discover tailored solutions for your specific needs, we invite you to download the Croft catalog and get in touch with us today. Let us empower your well site with cutting-edge technology and reliable support to unlock the full potential of your natural gas resources. Together, we can fuel a sustainable future.