In the oil and gas industry, natural gas dehydration plays a crucial role in ensuring safety, efficiency, and meeting pipeline specifications. Over-saturated gas can lead to corrosion, equipment damage, and non-compliance with industry standards. Gas dehydration removes excess water vapor from natural gas streams to combat these issues. In this blog post, we will delve into the significance of gas dehydration, explore the expert solutions offered by Croft Production Systems, and highlight the benefits of their customized dehydration equipment.

The Importance of Dehydrating Natural Gas

Dehydrating natural gas is paramount to eliminating water vapor from the gas stream. Water vapor in natural gas can lead to the formation of hydrates, oversaturation, and equipment corrosion. Hydrates are crystallized compounds of hydrocarbons and water, forming in high-pressure well streams with low temperatures. However, hydrates can also occur at temperatures above freezing point due to increased pressure and water vapor. These hydrates can cause blockages in pipelines, valves, and equipment, disrupting production. Additionally, oversaturated gas that does not meet pipeline specifications of 7 pounds per MMCFD must be dehydrated before being sold.

When water is in liquid form, it contributes to equipment corrosion. To avoid these harmful effects, natural gas is dehydrated by condensing it from vapor into liquid form and then removing the water through adsorption. The industry can safeguard against hydrate formation and corrosion by ensuring proper gas dehydration and maintaining compliance with pipeline specifications.

Understanding the Gas Dehydration Process

Gas dehydration involves the removal of water vapor from natural gas to prevent corrosion and ensure the gas meets pipeline specifications. When natural gas is over-saturated with water vapor, it can cause damage to gas processing equipment and reduce the overall efficiency of operations. The gas is condensed into liquid form and then separated using a gas dehydration unit to address this.

There are two primary methods used in gas dehydration: adsorption and absorption. Croft Production Systems excels in providing two types of natural gas dehydration equipment: Passive Dehydration Systems (PDS) that use solid desiccant dehydrators and Glycol Dehydrators (TEG).

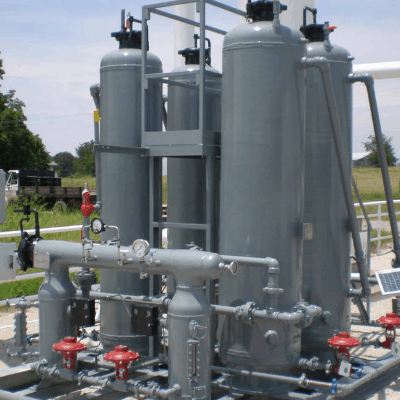

Passive Dehydration Systems (PDS)

Croft’s Passive Dehydration Systems utilize solid desiccants to remove water vapor from natural gas effectively. This is also called Desiccant Dehydration. These systems used hygroscopic substances to induce or sustain dryness. They are designed to operate without external power, making them a cost-effective, safe, and environmentally friendly solution. A PDS unit is a reliable choice for locations with limited power availability or remote oil and gas facilities.

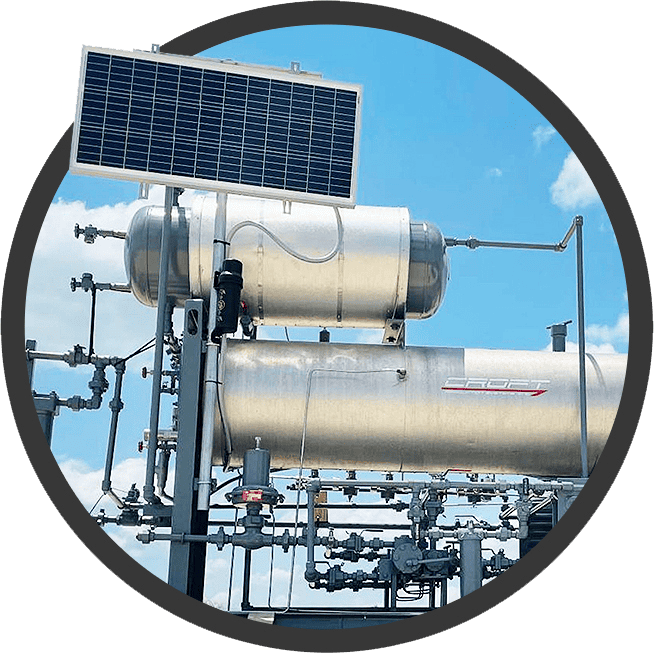

Glycol Dehydrators (TEG)

Croft offers a liquid chemical system to remove from natural gas and NGLs for more demanding applications. Glycol Dehydrators use Triethylene Glycol (TEG) as the desiccant. These systems are highly efficient and can handle larger volumes of natural gas. Croft’s Glycol Dehydrators have advanced features for precise control and monitoring, ensuring optimal performance.

Benefits of Using Croft’s Customized Solutions for Gas Dehydration:

Enhanced Safety

Proper gas dehydration reduces the risk of equipment corrosion, ensuring safe and reliable operations within the oil and gas industry.

Improved Efficiency

Dehydrated natural gas is more efficient to process and transport, leading to cost savings and improved overall productivity.

Compliance with Pipeline Specifications

Croft’s gas dehydration equipment ensures the natural gas meets pipeline specifications, avoiding costly penalties and downtime.

Tailored Solutions

Croft Production Systems offers customized gas dehydration solutions designed to meet the unique requirements of each client’s operation.

Comparing TEG and PDS for Gas Dehydration

Triethylene glycol (TEG) units are commonly used for gas dehydration but have significant safety and environmental concerns. TEG systems have multiple moving parts, open flames, and emit toxic pollutants, including hazardous air pollutants (HAPs) and volatile organic compounds (VOCs), posing risks to operators and the environment.

Passive Dehydration Systems (PDS) offered by Croft Production Systems provide a safer and more sustainable alternative. PDS units have no moving parts or open flames, ensuring minimal maintenance and zero emissions. They eliminate the need for permits and comply with stringent environmental regulations, making them a unanimous choice for safe natural gas dehydration.

Environmental Considerations

TEG units emit harmful VOCs like propane, benzene, and formaldehyde, which can cause health issues, and HAPs are known to cause cancer and other serious health effects. The methane emissions from TEG units are substantial, contributing to greenhouse gas effects that are 21 times greater than carbon dioxide. In contrast, PDS units emit negligible amounts of methane and dispose of waste as a non-hazardous brine solution.

Choosing PDS over TEG units means reducing environmental and health liabilities, conserving natural resources, and complying with environmental regulations. PDS is a safer and environmentally responsible choice for gas dehydration applications.

Croft Production Systems – The Leader in Gas Dehydration

Gas dehydration is critical in the oil and gas industry, safeguarding equipment, ensuring compliance, and enhancing efficiency. Croft Production Systems is a trusted partner providing expertly designed and manufactured gas dehydration equipment. Their customized solutions, including Passive Dehydration Systems and Glycol Dehydrators, offer safety, efficiency, and compliance for various applications. We’re the industry leader you can rely on for top-quality equipment and exceptional service. Contact us today to discuss how we can help your operations today!