Frequently Asked Questions

Introduction In a glycol dehydration system, maintaining the health of your Tri ethylene Glycol (T.E.G.) is critical. Over time, glycol often becomes acidic due to thermal decomposition, the presence of oxygen and acid gases, or carryover into the unit. Left unchecked, acidic glycol leads to severe corrosion and equipment failure. Today, we’re covering the essential […]

Introduction Today we’re at a natural gas dehydration unit, often called a glycol system. Now these systems are used to dehydrate the natural gas by removing the water vapor that’s present in the natural gas to reduce corrosion and prevent hydrate formation. Now the way this system works is the gas will enter through the […]

Introduction Today we’re at a natural gas dehydration unit, often called a glycol system. Now these systems are used to dehydrate the natural gas by removing the water vapor that’s present in the natural gas to reduce corrosion and prevent hydrate formation. Now the way this system works is the gas will enter through the […]

In the world of natural gas midstream and upstream operations, hydrogen sulfide (H2S) is a constant adversary. Left untreated, it corrodes infrastructure, poses severe health risks, and prevents gas from meeting pipeline quality specifications. Among the various desulfurization technologies available, Iron Oxide Systems (IOS)—often referred to as “iron sponge” or “solid bed scavengers”—remain a gold […]

An amine plant, also known as an amine treating unit or gas sweetening unit, is a critical component in the oil and gas industry, designed to remove acidic components—primarily hydrogen sulfide H2S and carbon dioxide CO2 —from natural gas and other process streams. This process is essential for meeting pipeline specifications, protecting equipment from corrosion, […]

Industrial burners sit at the center of many oil and gas processing operations. From glycol dehydration units and amine plants to line heaters and fired process heaters, safe and efficient combustion is critical to production reliability, operating costs, and personnel safety. Yet burners are often treated as “set it and forget it” equipment. Over time, […]

Complete Glycol Dehydration System Maintenance from Inspection to Startup Triethylene Glycol (TEG) dehydration systems are mission-critical assets in natural gas processing. When a TEG unit underperforms, the consequences are immediate—off-spec gas, excessive glycol losses, foaming, corrosion, and unplanned shutdowns. That’s why professional TEG cleanout and overhaul services are essential for operators seeking reliable dehydration performance […]

Case Study Blog: How Chlorides Affect Glycol Dehydrators in Natural Gas Processing Glycol dehydration units are critical in the natural gas industry for removing water vapor from raw gas streams to meet pipeline and sales gas specifications. Among the many contaminants and operational challenges that glycol dehydrators face, chlorides (e.g., NaCl, CaCl₂, MgCl₂) stand out […]

The Due Diligence Deep Dive: Top 10 Questions to Ask Before Buying a Glycol Dehydrator In the world of natural gas processing, removing water vapor is not just a regulatory requirement—it’s a fundamental necessity for preventing corrosion, inhibiting the formation of dangerous gas hydrates, and ensuring the gas meets pipeline quality specifications typically 7 pounds […]

The Due Diligence Deep Dive: Top 10 Questions to Ask Before Buying a JT Plant In the upstream and midstream sectors of the oil and gas industry, efficiency, recovery, and regulatory compliance are the cornerstones of profitability. A Joule-Thomson (JT) Plant—a simple, elegant piece of technology leveraging the cooling effect of gas expansion—is often the […]

What is Hydrolancing Hydrolancing, also known as jet cleaning or high-pressure water blasting. It is a type of cleaning method using a high-pressure water jetting process removing scales, deposits, and buildup from the interior and exterior of gas processing and production equipment. Heat exchangers, glycol dehydrators and piping systems overtime can produce buildups that will […]

What are Fin Fans Fin fans are industrial air-cooled heat exchangers (ACHEs) that are critical components in oil and gas processing equipment, natural gas dehydration systems and refineries. They use ambient air to cool and process fluids flowing through the tubes as a cooling medium. Over time these units tend to collect dust, dirt, and other debris, […]

In the vast and intricate world of the oil and gas industry, understanding specific equipment and processes can be daunting for many. Wikipedia, the go-to source for quick definitions, describes a workover rig in the following manner: “The term workover is used to refer to any oil well intervention involving invasive techniques, such as wireline, […]

Acid gas is a type of natural gas that contains significant quantities of hydrogen sulfide (H2S), carbon dioxide (CO2), or similar acidic gasses.

Get answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

Get answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

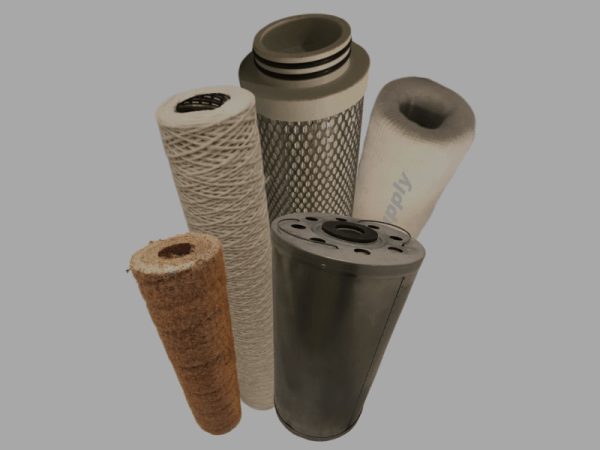

Get answers to our client’s most frequently asked questions about filtration for amine plants, glycol dehydrators, and coalescing filters.

Croft Production Systems offers skid-mounted Joule Thomson Systems that simultaneously reduces the water dew point of gas, recovers valuable hydrocarbon liquids, and lowers the BTU

Absorption vs. Adsorption Dehydrating natural gas, or the removal of water vapor from natural gas can be done by either adsorption or absorption. Croft’s Passive Dehydration System uses adsorption, where water vapor is collected and condensed on the surface with the use of a solid desiccant. Solid desiccants have a high adsorption capacity, a low resistance to gas […]