Coalescing Filtration and Gas Separators: A Closer Look

Separating contaminants from gas streams is vital for many industries to ensure product quality, operational efficiency, and environmental safety. Among the various technologies and equipment used for this purpose, coalescing filtration, often referred to as coalescing gas separators, stands out for its specific design aimed at eliminating finer contaminants like mists, fogs, and dust.

What Contaminants Do They Target?

The contaminants that coalescing filters target are primarily minute particles that are often challenging to separate using conventional methods. A significant characteristic of these contaminants is their tiny size. Most of these particles are smaller than 10 microns in diameter. A human hair’s width ranges between 50 to 70 microns. Due to their size, these ultra-fine contaminants can easily remain suspended in the gas streams and may not be effectively captured by standard separators or scrubbers.

Why is their Size a Challenge?

Particles that are considerably less than 10 microns in diameter pose a unique challenge. Their tiny size means they have a larger surface area relative to their volume, resulting in higher drag forces acting upon them in a gas stream. This makes them less susceptible to separation through traditional means, such as gravitational settling. Moreover, these particles, especially when present in the form of mist or fog, can easily re-entrain into the gas stream, making their removal even more challenging.

Coalescing Filtration: The Solution

Coalescing gas separators are equipped with special filter media that promote the aggregation or coalescing of these tiny particles. When these particles come into contact with the coalescing media, they merge or ‘coalesce’ to form larger droplets. These larger droplets can then be more easily separated from the gas stream using gravitational methods or other separation techniques.

This unique mechanism allows coalescing filters to capture and remove particles that would otherwise escape more conventional separators or scrubbers.

Further Reading

For those interested in a deeper understanding of coalescing filters, including their design, operation, and applications, we have previously written a comprehensive blog post on the subject. This blog offers insights into what a coalescing filter is, how it operates, and the advantages it brings to industries requiring efficient gas purification.

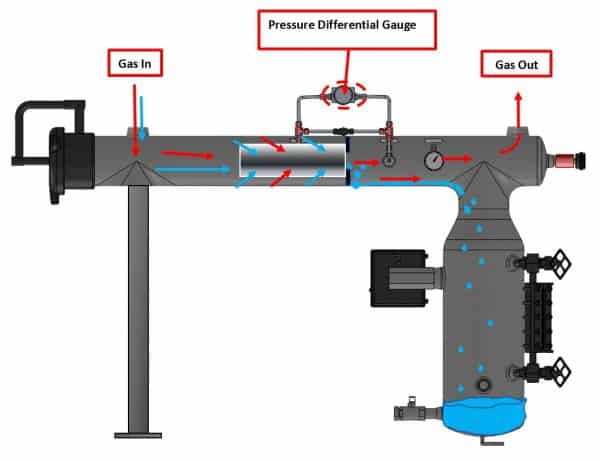

How do coalescing filters work?

Gas containing entrained liquid, mist, fog, dust, rust or scale enters the vessel through the inlet connection into the large inlet chamber ahead of the coalescing elements. This allows the gas to distribute around the coalescing elements to use the available filter surface area efficiently. Solid particulate materials are trapped by the filter element fibers as the gas and liquids pass through. The liquid, mist, or fog is retained by the fibers of the filter element until enough liquid accumulates to form a large drop. The gas then forces the large drops through the filter element. These large drops are then separated from the gas by gravity or by the action of the mist extractor section.

The liquid accumulates in the liquid chamber, where it is removed by the action of the liquid level controller and dump valve. The liquid accumulation may have a specially constructed wire screen divider that prevents liquid from being re-entrained into the gas stream. The gas, free from its particulate contaminants and liquids, leaves the vessel through the gas outlet.

Gas containing entrained liquid, mist, fog, dust, rust, and scale enters the vessel through the inlet connection near the top of the vessel. The gas is deflected around the shell of the large inlet chamber by a deflector plate so that the gas stream does not impinge upon the coalescing elements. This allows the gas to distribute around the coalescing elements to use the available filter surface area efficiently. Solid particulate materials are trapped by the filter element fibers as the gas and liquids pass through. The liquid mist or fog is retained by the fibers of the filter element until enough liquid accumulates to form a large drop. The gas then forces the large drops through the filter element. These large drops are then separated from the gas by gravity or by the action of the mist extractor section.

The liquid accumulates upon the center diaphragm plate immediately above the gas outlet and then flows through the center downcomer into the lower liquid accumulation section, where it is removed by the action of the liquid level controller and dump valve. The gas also flows through the center downcomer into the liquid accumulation section, reversing direction and passing through the wire mesh mist extractor. The gas, free from its particulates, contaminates and liquids, leaves the vessel through the gas outlet in the center of the vessel. Liquid accumulating in the coalescing element chamber is removed by the action of the liquid level controller and dump valve.

In our previous blog, What is a Coalescing Filter? We explained what it is and its functions. Below is the picture to show the process.

Coalescing filters can be equipped with standard accessories. These can be used for both vertical and horizontal filters. Many of these accessories can be purchased at CroftSupply.com.

- ASME Code shell

- Set of coalescing elements

- Mist extractor (vane type or wire mesh)

- Liquid level controller

- Liquid dump valve

- Pressure gauge with 2 isolation valves and piping manifold

- Liquid level gauge assembly

- Differential pressure indicator

- Pressure relief valve

- Isolation block valve on liquid dump line

- By-pass piping manifold with block and by-pass valves

- Spare sets of coalescing elements

Buy parts for a coalescing gas separator.

Sell your used coalescing gas separator.

Buy used coalescing gas separator.

Request a quote for a manufactured coalescing gas separator.