Cameron P. Croft

Founder and CEO

Mr. Croft graduated from the University of Houston with a Bachelor of Science in Mechanical Engineering Technology and holds a Master of Science in Technology Project Management with a black belt in Lean Six Sigma. Since 2006, Mr. Croft has served as the founder/CEO of several other natural gas processing companies including Croft Production Systems and Croft Supply. In 2019, Mr. Croft established the Surplus Energy Equipment with a team of engineers that have been in the oil and natural gas industry for over 10 years. He designed this platform to allow clients to see a full line of equipment without having to make phone calls to vendors or spend time searching for quality equipment. His focus now is building relationships with partners and expanding on CROFT's product lines.

Find me LinkedIn: https://www.linkedin.com/in/cameron-p-croft/

Most customers dread having to conduct a full cleanout of a TEG dehydrator. The cleanout sometimes implies shutdowns or drop in capacity. One of the ways CROFT designed the Passive Dehydration System (PDS) is to be utilized as a quick, easy, and a temporary way to bypass a TEG and continue to dehydrate the gas while your TEG is shut down and getting serviced/cleaned out.

The CIS 30 MM model. This system was designed to have different static mixers to create enough turbulence and increase contact time without creating too much of a pressure differential. It has a modified two-phase separator to act as a bubble tower for efficient use of the chemical while providing proper separation.

natural gas processing has several steps, the main processes include separation, carbon dioxide and hydrogen sulfide removal, dehydration, and NGL recovery.

Absorption vs. Adsorption Dehydrating natural gas, or the removal of water vapor from natural gas can be done by either adsorption or absorption. Croft’s Passive Dehydration System uses adsorption, where water vapor is collected and condensed on the surface with the use of a solid desiccant. Solid desiccants have a high adsorption capacity, a low resistance to gas […]

Gas dehydration is the removal of water from the gas stream in order to meet pipeline specifications.

CROFT Passive Dehydration Systems natural gas dehydration unit that utilizes a specially formulated solid desiccant called enviroDRI to adsorb water from the gas stream. Below are our clients’ most commonly asked questions about enviroDRI. What is enviroDRI? enviroDRI is a deliquescent desiccant pellet about the size of an almond designed to adsorb water from hydrocarbon […]

The Passive Dehydration System is the preferred alternative to the glycol unit for natural gas dehydration. Dehydration is a critical process required to meet pipeline specifications.

Dual Fuel Powered Drilling Rigs and Frac Spreads Many cost-conscious oilfield companies have made the switch to either natural gas or dual-fuel, also referred to as bi-fuel, which is a mixture of diesel and natural gas. Dual-fuel engines run on a combination of diesel and natural gas, giving companies the flexibility to choose which fuel […]

Oil storage tanks serve as a staging area to collect crude oil in several stages of production. These tanks are used in production fields and hold the oil until it is delivered to tankers or into a pipeline. Storage tanks are also used as a holding area for crude oil before the refining process and they also hold refined products after it is processed.

Coalescing Filtration and Gas Separators: A Closer Look Separating contaminants from gas streams is vital for many industries to ensure product quality, operational efficiency, and environmental safety. Among the various technologies and equipment used for this purpose, coalescing filtration, often referred to as coalescing gas separators, stands out for its specific design aimed at eliminating […]

Coalescing gas separators (or coalescing separators) are designed specifically for the removal of mist, fogs, and dust from gas streams. Standard separators cannot remove these small, minute contaminants in the gas stream because particles are usually less than 10 microns. A coalescing gas separator consist of a vessel, combining specially constructed coalescing elements and a […]

Croft Production Systems, Inc. is excited to announce that we are now an authorized dealer for Genis Holdings, LLC for the Aeris Gas Cooler, a gas-powered air cooler. Genis and PC3 Technologies, LLC were established in 2017 to find ways for to improve an industry that had not seen many changes in over 50 years, specifically on […]

How to prepare oil and gas processing for winter Why is winter hard on production and processing? Two words; hydrate formations. Hydrates are crystals formed when water and gas are combined in a low temperature and high-pressure environment. They become more prevalent during colder ambient temperatures. During the colder ambient temperatures, water vapor will begin to condense which can cause […]

A separator is a mechanical device for removing and collecting liquids from natural gas. Read our blog on What is a Separator? to learn more about the specific applications for a separator. Now, let’s dive in on the specifics of how a separator works and understanding the process a little more in-depth. The Separation Process: All separators […]

An oil and gas separator is used for removing and collecting liquids from natural gas. A properly designed separator will also provide the release of entrained gases from the accumulated hydrocarbon liquids. These separators can go by many names or different purposes like liquid separators, oil separators, water and oil separators, etc., but the most […]

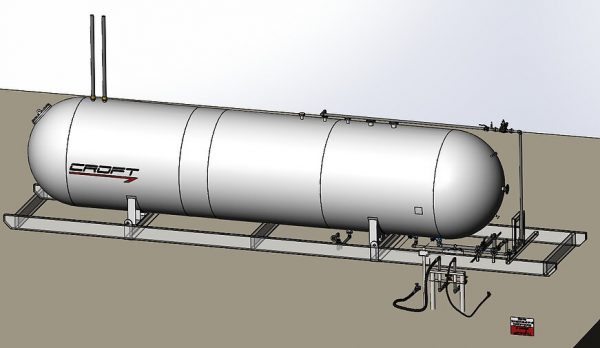

Engineer, Eric Orellana, talks about bullet tanks, their features and NGL recovery. Read more about CROFT bullet tanks and their features. What is a Bullet Tank? Transcription Hi, my name is Eric Orellana, I’m an engineer here at Croft Production Systems. Today I’ll be talking to you about bullet tanks and some of their features. […]

We are excited to spotlight one of our partners, EcoVapor Recovery Systems. CROFT values this relationship because EcoVapor’s dedication matches CROFT’s commitment to environmental controls. EcoVapor Recovery Systems helps its clients achieve a ZERO Emissions facility while improving free cash flow and site safety. With their extensive expertise in tank vapor management and vapor recovery systems, […]

There are many guidelines that our industry must follow to ensure there is a safe environment for everyone. At CROFT, we follow the same standard and safety guidelines for all of our equipment and bullet tanks are no exception. Last week we told you what a bullet tank was and what it is used for. […]

A bullet tank is a storage container that houses natural gas liquids (NGLs). The tanks come in many different sizes and include accessories that best suit your operation. Bullet tanks range from 6,000 to 30,000 gallons, with an 18,000-gallon tank being the most common size. Tanks should be no more than 70-80% full in order for […]

Service Lead, Eric Gorka, takes us on our first Field Trip and shows us how to Measure Water Vapor. To properly measure water vapor, you will need the following tools: Gas Detection Tubes/Colorimetric tubes Puller The gas bulb of hard plastic or stainless steel How to measure: Install bulb Purge bulb Break each end of the […]