Our Products

This virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

This virtual roundtable discussion explores topics related to processes and equipment used in CO2 and H2S removal.

Get answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

Get answers to our client’s most frequently asked questions about our Fuel Gas Conditioning System (FCS)

This case study will focus on treating fuel gas for gas lifts utilizing CROFT’s Fuel Gas Conditioning System.

This webinar provides education on fuel gas and JTs. Our Director of Engineering focuses on cleaning up fuel gas and getting natural gas to pipeline specification.

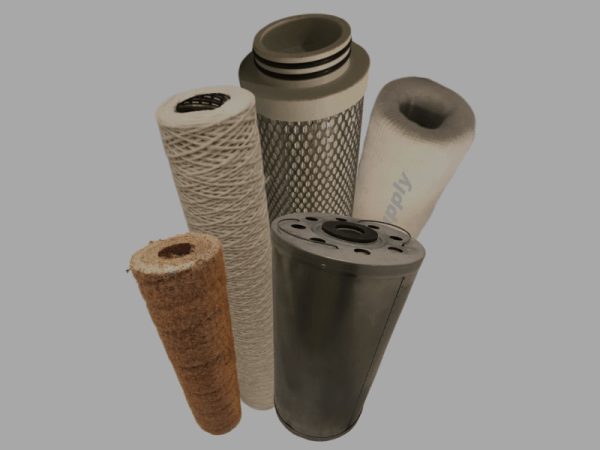

Get answers to our client’s most frequently asked questions about filtration for amine plants, glycol dehydrators, and coalescing filters.

This case study will focus on optimizing filtration for amine plants and glycol dehydrators, therefore decreasing shutdown time and saving money.

This webinar provides education on fuel gas and JTs. Our Director of Engineering focuses on cleaning up fuel gas and getting natural gas to pipeline specification.

Croft Production Systems offers skid-mounted Joule Thomson Systems that simultaneously reduces the water dew point of gas, recovers valuable hydrocarbon liquids, and lowers the BTU

This case study will focus on CROFTs Joule Thomson System reducing the BTU while treating gas utilized for fuel purposes in compressor engines.

Most customers dread having to conduct a full cleanout of a TEG dehydrator. The cleanout sometimes implies shutdowns or drop in capacity. One of the ways CROFT designed the Passive Dehydration System (PDS) is to be utilized as a quick, easy, and a temporary way to bypass a TEG and continue to dehydrate the gas while your TEG is shut down and getting serviced/cleaned out.

In this webinar, Saving Money in Operations: Glycol Dehydration, we engage with experts discussing glycol dehydration units and optimization.

Most customers dread having to conduct a full cleanout of a TEG dehydrator. The cleanout sometimes implies shutdowns or drop in capacity. One of the ways CROFT designed the Passive Dehydration System (PDS) is to be utilized as a quick, easy, and a temporary way to bypass a TEG and continue to dehydrate the gas while your TEG is shut down and getting serviced/cleaned out.

The CIS 30 MM model. This system was designed to have different static mixers to create enough turbulence and increase contact time without creating too much of a pressure differential. It has a modified two-phase separator to act as a bubble tower for efficient use of the chemical while providing proper separation.

Absorption vs. Adsorption Dehydrating natural gas, or the removal of water vapor from natural gas can be done by either adsorption or absorption. Croft’s Passive Dehydration System uses adsorption, where water vapor is collected and condensed on the surface with the use of a solid desiccant. Solid desiccants have a high adsorption capacity, a low resistance to gas […]

CROFT Passive Dehydration Systems natural gas dehydration unit that utilizes a specially formulated solid desiccant called enviroDRI to adsorb water from the gas stream. Below are our clients’ most commonly asked questions about enviroDRI. What is enviroDRI? enviroDRI is a deliquescent desiccant pellet about the size of an almond designed to adsorb water from hydrocarbon […]

Solid desiccant dehydration is a safer alternative to gycol dehydration, which uses a liquid desiccant to absorb water from the gas.

The Passive Dehydration System is the preferred alternative to the glycol unit for natural gas dehydration. Dehydration is a critical process required to meet pipeline specifications.

- « Previous

- 1

- 2

- 3

- Next »